The Importance of CAD in Waste-to-Energy Technology Processes

Have you ever wondered what happens to the mountains of waste generated by modern society? Could there be a way to turn that waste into something beneficial, like energy? As landfills reach capacity and the demand for renewable energy grows, waste-to-energy (WTE) technologies are emerging as a revolutionary solution. These processes offer a way to manage waste sustainably while generating usable energy. However, their development and optimization require a blend of innovative thinking and cutting-edge technology. This is where Computer-Aided Design (CAD) steps in, providing the tools to visualize, simulate, and refine WTE systems with precision and efficiency.

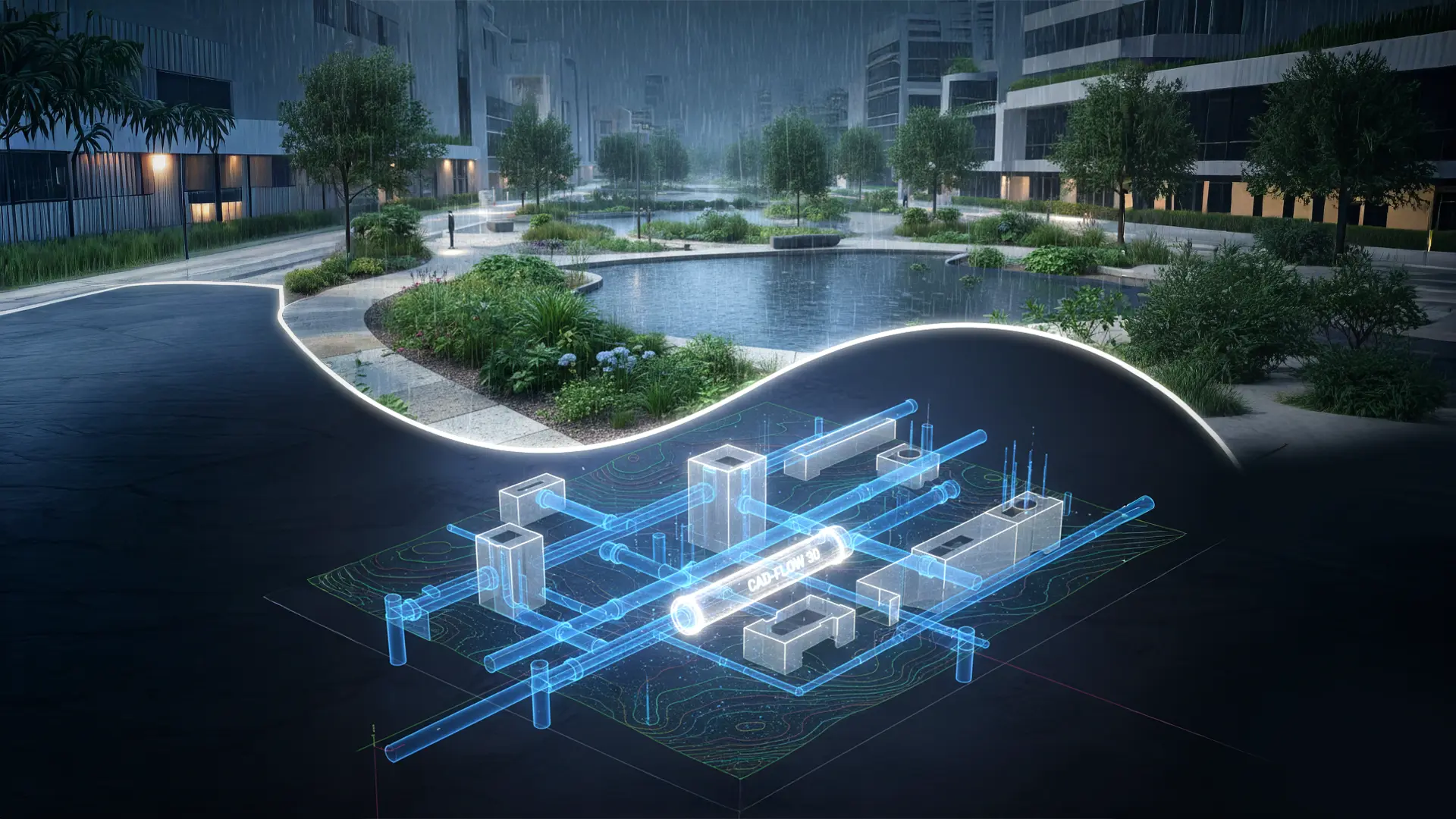

As we delve into the world of waste-to-energy, the role of CAD becomes pivotal in overcoming design challenges, minimizing environmental impacts, and enhancing overall system performance. CAD Connect, a leader in advanced CAD services, has consistently demonstrated expertise in supporting industries like Water-Tech, Clean-Tech, and energy systems, making them a trusted partner for projects that demand technical excellence and sustainability-focused solutions. Explore our blog to understand how the intersection of CAD, virtual simulations, and waste-to-energy technologies play a key role in creating sustainable solutions required for the future.

Understanding Waste-to-Energy Technology

Waste-to-energy technology transforms non-recyclable waste into usable forms of energy such as heat, electricity, or fuel. This not only reduces the volume of waste destined for landfills but also provides an alternative energy source, helping to mitigate the strain on traditional power systems. Methods like incineration, gasification, and anaerobic digestion lie at the heart of WTE. Incineration involves burning waste at high temperatures, reducing its mass and generating energy. Gasification exposes organic materials to a low-oxygen environment, producing syngas that can be used as fuel. Anaerobic digestion, meanwhile, uses microorganisms to break down organic waste in oxygen-free environments, yielding biogas as an energy source.

While these methods present significant benefits, including reduced waste and greenhouse gas emissions, they also come with challenges. Emissions control, public perception, and the complexity of waste sorting and processing require innovative engineering solutions to ensure WTE technologies remain both effective and environmentally friendly. This is where CAD tools, with their precision and flexibility, play an essential role in designing and optimizing these systems.

The Role of CAD and Virtual Simulations in Engineering WTE Systems

The integration of CAD (Computer-Aided Design) technology into the design and engineering of Waste-to-Energy (WTE) plants has revolutionized how these systems are conceptualized, tested, and implemented. CAD tools provide engineers with the ability to create detailed, accurate virtual models that streamline the design process. In the early stages, CAD software enables teams to visualize and refine system configurations, ensuring that different design alternatives are explored before any physical construction begins. As the project advances, CAD tools allow engineers to analyse structural integrity, assess energy efficiency, and optimize system performance by simulating various real-world conditions.

Popular CAD tools like AutoCAD, SolidWorks, and COMSOL Multiphysics are commonly used in WTE projects. AutoCAD’s drafting capabilities, SolidWorks’ advanced 3D modelling features, and COMSOL’s specialized simulation tools enable the creation of precise models that can be iteratively tested and refined. This virtual testing minimizes the need for costly physical prototypes, speeding up the design process and reducing the risk of costly mistakes.

Virtual simulations, integrated into CAD workflows, further enhance the engineering of WTE systems by enabling the simulation of thermal dynamics, fluid flow, and material behaviour. These simulations play a crucial role in optimizing waste management and energy production. For example, simulating waste combustion processes helps reduce harmful emissions while maximizing energy recovery, and in gasification, simulations optimize operational parameters to enhance syngas production. Moreover, virtual simulations support lifecycle assessments, providing insights into the overall environmental impact of WTE systems, from waste generation to disposal.

By integrating these advanced CAD tools and virtual simulations, CAD Connect ensures that every aspect of WTE system design is thoroughly optimized for efficiency and sustainability. Its expertise enables engineers to create more precise, reliable, and cost-effective solutions, paving the way for innovative waste-to-energy systems. Through tailored CAD solutions, CAD Connect helps drive the success of these projects, delivering high-performance systems that meet both environmental and operational goals.

Challenges in Implementing Virtual Simulations for Waste-to-Energy Technology

Despite their advantages, virtual simulations come with challenges. Accurately modelling the heterogeneous nature of waste materials remains a complex task. Waste can vary significantly in composition and properties, making it difficult to achieve precise simulations. Additionally, advanced simulations often require significant computational resources, which can be a barrier for smaller organizations.

Integrating different WTE technologies within a single simulation framework adds another layer of complexity. However, ongoing advancements in simulation software and modelling techniques are gradually addressing these issues, paving the way for more accurate and accessible tools. CAD Connect remains at the forefront of these developments, offering solutions that balance cutting-edge technology with practical, scalable implementation.

Future Trends in Virtual Simulations for WTE

Looking ahead, virtual simulations for waste-to-energy (WTE) systems are set to become even more advanced, driven by emerging technologies like machine learning and artificial intelligence. These innovations are transforming the way WTE plants operate by enabling predictive maintenance. Simulations powered by AI can analyze historical data alongside real-time performance to anticipate equipment failures and maintenance needs, reducing downtime and optimizing operational efficiency. As these technologies continue to evolve, they will enhance the reliability and longevity of WTE facilities, ensuring that energy recovery processes are more efficient and cost-effective. This shift towards smarter simulations also means that WTE systems can be continuously optimized, leading to better waste management and cleaner energy production. With the potential for further integration of digital twins and cloud-based platforms, the future of WTE systems is brighter, offering more sustainable and efficient solutions for waste-to-energy conversion.

Waste-to-energy technologies represent a promising solution to the dual challenges of waste management and energy production. The role of CAD in this sector is transformative, providing the precision and flexibility needed to design and optimize complex systems. Virtual simulations have unlocked new possibilities for improving efficiency, reducing costs, and minimizing environmental impacts. CAD Connect’s expertise in advanced CAD services positions it as a valuable partner in driving innovation in the WTE space. By embracing these technologies, the future of sustainable energy and waste management becomes increasingly achievable. Contact us today to explore how we can contribute to your next waste-to-energy conversion project.