Strategies to Modernize Industrial Water Management with CAD

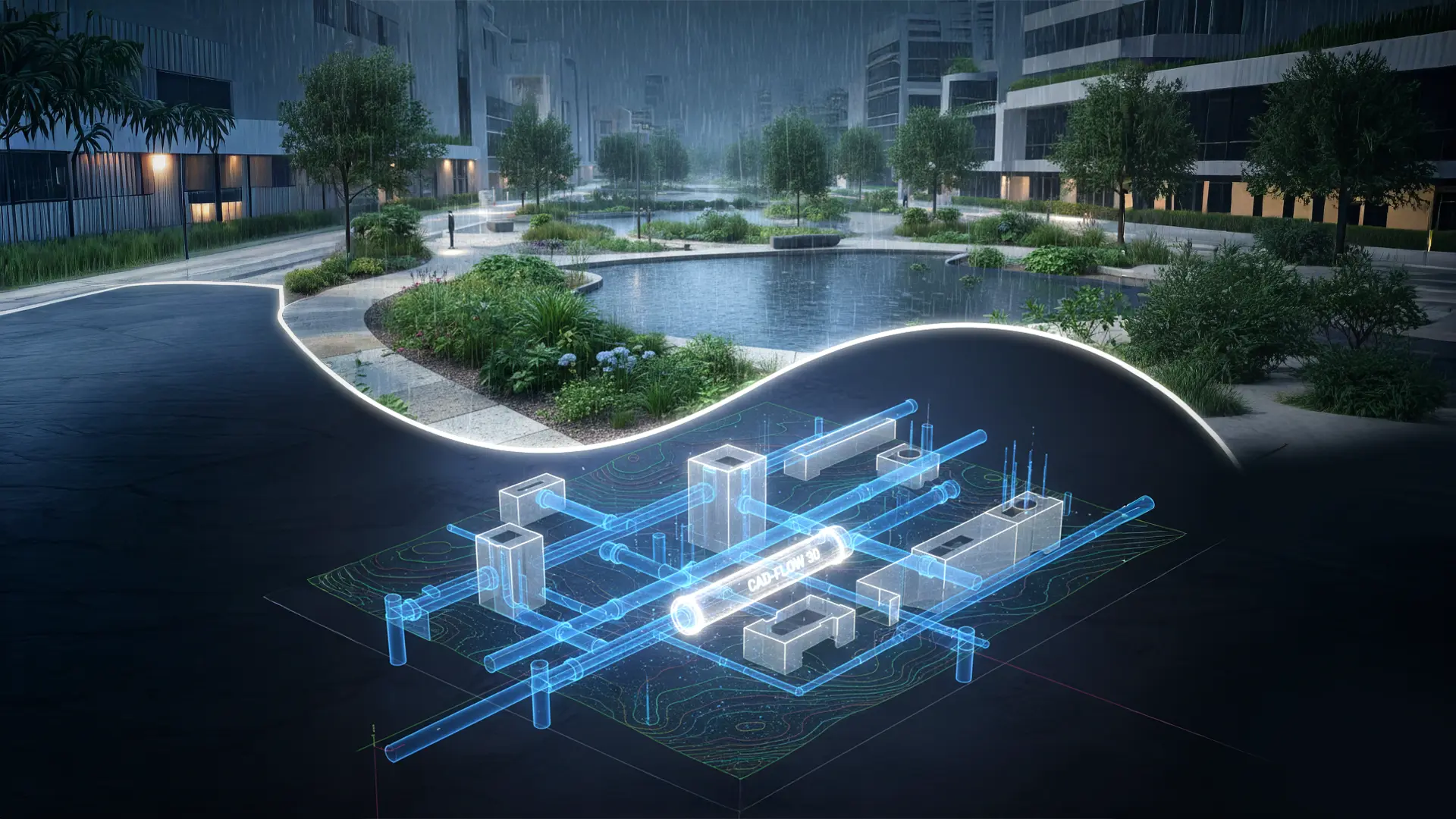

Ever wondered how industries would use technology to manage their water resources efficiently? Optimizing water usage, enhancing treatment procedures, and guaranteeing sustainability have emerged as critical issues in today’s hectic industrial setting. This is where CAD, or computer-aided design, becomes revolutionary.

Innovation has become essential in the dynamic field of industrial water management.Water resource management is becoming more and more difficult for industries globally to function effectively, safely, and sustainably. Companies are investigating new technologies as a result of regulatory restrictions and the scarcity of water, which ultimately calls for a need for cleaner processes. Industrial water management is undergoing a revolution because of CAD (Computer-Aided Design), a tool that was previously only used in engineering and architecture.

We CAD Connect, have extensive experience of CAD integration into water management systems that has revolutionized conventional procedures. This blog examines how computer-aided design (CAD) is gaining popularity in this domain and how we, as leaders in 2D and 3D CAD services, are enabling various businesses to effectively address water management issues.

Overview of CAD in Industrial Applications

Designing, drawing, and modeling systems, structures, and products is done with software known as CAD (Computer-Aided Design). It is used in many different areas, including engineering analysis, building, manufacturing, and product design. CAD is essential in industrial operations because it improves precision, shortens development times, and permits simulations and optimizations.

Beginning with simple 2D drafting tools, CAD has been used in the aerospace and automotive industries since the 1960s. With the advent of software like AutoCAD, CAD became widely used in various industries by the 1980s. Modern CAD incorporates sophisticated simulations and cloud-based collaboration, while 3D CAD was first used in the 1990s for realistic modeling and prototyping.

Evolution of CAD in Water Management

Water management systems have benefited greatly from CAD’s improved design of distribution networks, treatment facilities, and pipes. CAD was first used for drafting, but it is now integrated with 3D modeling and hydraulic simulations to optimize equipment location and water flow. Smart water systems are a recent development that combines CAD and IoT technology to produce more effective and sustainable water management solutions.

From simple drafting tools to necessary industry-wide technology, CAD has developed over time. It continues to spur innovation in water management, enhancing system design and operation sustainability and efficiency.

The Role of CAD in Designing Water Management Systems

The use of CAD has revolutionized the way engineers plan and create water management systems. CAD makes it possible to create infrastructure that is dependable, sustainable, and efficient by integrating cutting-edge tools and simulations. The following are some significant ways that CAD improves water management system design:

- How CAD Helps in Planning and Designing Efficient Water Infrastructure

Engineers can design water systems with precision using CAD, including pipelines, reservoirs, and treatment facilities. CAD promotes optimal system performance by avoiding waste and eliminating inefficiencies by modeling water flow and pressure. This makes it easier and more economical for engineers to handle difficult problems like the distribution, storage, and treatment of water.

- Integration of Hydraulic and Environmental Data in CAD Models

Through the use of hydraulic models and environmental data integration, modern CAD tools enable engineers to forecast the effects of weather, terrain, and water flow rates on the system. This integration aids in the design of infrastructure that ensures long-term reliability by improving sustainability, adapting to changing conditions, and meeting regulatory criteria.

- Benefits of 3D Visualization in Water Management

Before construction, a thorough, accurate picture of water management systems may be seen thanks to the use of 3D visualization in CAD. Engineers are able to see intricate relationships between different parts, identify possible problems, and arrange equipment for maximum efficiency. Additionally, this skill aids stakeholders in making better decisions and minimizing expensive implementation failures by enhancing their understanding of designs.

Because of these features, computer-aided design (CAD) has become a vital tool for developing contemporary water management systems, spurring efficiency and innovation in the sector.

Advantages of CAD in Water Management Processes: Revolutionizing Efficiency and Reliability

Imagine organizing a major water management project, including developing treatment facilities that can adapt to changing water demands and constructing intricate networks of pipelines. This procedure used to be drawn out, costly, and error-prone. However, CAD has completely changed the way we approach these tasks. In addition to streamlining the design process, CAD is essential to the sustainability and long-term viability of water management systems.

Reducing Costs and Time in Water Management Projects

Water management infrastructure took weeks of handwriting, multiple revisions, and expensive prototypes to create detailed plans in the past. All of that has changed with CAD. CAD dramatically reduces the amount of time spent on the design stage by enabling automated simulations and real-time design revisions. Engineers can quickly test various configurations and scenarios, preventing delays and cutting expenses associated with personnel, materials, and building.

Projects that used to take months can now be completed in a fraction of the time without compromising accuracy or quality.

Improving Accuracy and Efficiency of Water System Designs

Engineers can precisely regulate even the smallest features of their designs with the help of CAD technologies. When it comes to simulating pump and valve performance or modeling the flow of water through pipes, CAD makes sure that every component of a water management system is optimized for effectiveness. Engineers may build systems that take into consideration real-world variables, minimize errors, and guarantee that systems operate efficiently under a variety of scenarios by integrating geographical and environmental data.

This degree of accuracy ensures that projects are finished on schedule and within budget by reducing the possibility of expensive rework and enhancing system reliability.

CAD’s Role in Predictive Maintenance and Risk Management

The capacity of CAD to facilitate risk mitigation and predictive maintenance is among its most notable benefits. Engineers can discover possible weak points, such as locations prone to leaks, wear, or environmental stress, by simulating the performance of a water system over time. Systems with built-in redundancies can be designed thanks to CAD, which guarantees that maintenance requirements are recognized and met before problems happen.

Additionally, by leveraging historical data and predictive analytics within CAD models, water management teams may proactively address dangers, saving downtime and extending the lifespan of the infrastructure.

Furthermore, water management teams can proactively address hazards, minimizing downtime and prolonging the lifespan of the infrastructure, by utilizing historical data and predictive analytics within CAD models.

CAD has transformed water management procedures by cutting costs, increasing design accuracy, and enabling predictive maintenance. Industries can provide more robust, cost-effective, and efficient water systems that last throughout time by embracing these technical advantages.

Educational and Training Requirements for CAD in Water Management

Water management has emerged as a critical issue in a quickly changing industrial world, particularly in light of the growing global consciousness of sustainability. One instrument that sticks out as a game-changer in the context of technology offering new solutions is CAD (Computer-Aided Design). But as sectors seek to implement cutting-edge CAD-driven water management systems, an important question is raised: Do we have qualified experts who can create these cutting-edge systems?

Let’s explore the journey of Emma, an engineer who went on to become an expert in water management using CAD. Her journey illustrates the necessary qualifications, training, and educational paths for anyone hoping to have a significant impact in this sector.

Emma’s Inaugural Steps into CAD for Water Management

Emma’s love for sustainable design has never wavered. She obtained employment in a water treatment plant following her graduation with a degree in environmental engineering. It didn’t take her long to identify the system’s shortcomings. High operating expenses, antiquated treatment designs, and leaks were common causes of water loss. She came to see that overhauling the infrastructure was the best way to address these problems.

Emma’s issue, though, was that she was unable to convert her concepts into workable designs. She then became acquainted with the field of CAD for water management.

The necessary competencies for designers and engineers using CAD in water management

Emma first believed that her knowledge of CAD would be sufficient. But the more she studied, the more she saw that designing for water management called for a special set of abilities not found in conventional CAD knowledge. To be successful, she had to become proficient in:

- Hydraulic Modeling

- Environmental Data Integration

- 3D Visualization and Simulation

- Problem-solving with Predictive Analytics.

Emma’s story is just a reminder of the immense potential of CAD as an advanced technology that can transform business operations seamlessly.

Future Trends in Industrial Water Management with CAD

Emerging technologies like artificial intelligence (AI), machine learning, and blockchain are expected to change industrial water management using CAD in the future by providing new opportunities for design, optimization, and auditing. By facilitating real-time, on-site design adjustments and encouraging international engineering collaboration, augmented reality (AR) and cloud computing are enhancing CAD. By automating intricate design procedures, AI and machine learning will enable CAD tools to optimize water systems through data-driven insights and modify designs in response to real-time environmental data. Blockchain technology, on the other hand, will completely transform system auditing by offering an unchangeable record of each design and maintenance action, increasing transparency, and guaranteeing regulatory compliance. In addition to streamlining water management as these technologies converge, CAD will encourage sustainability and accountability in the industry.

Challenges in Implementing CAD for Water Management

Even while CAD has the potential to revolutionize water management systems, its application is not without difficulties. Consider a water management engineer whose job is to plan a new treatment facility. Although CAD software is available to them, they quickly learn that it cannot handle the intricacy of water flow dynamics and integrate real-time environmental data due to its limits. Engineers find it challenging to accurately model fluid systems using current CAD technologies, which frequently lack specialized features needed to represent water behavior under various conditions.

The lack of training and expertise in CAD-based water management is another serious problem. A lot of engineers are used to working with conventional techniques. Therefore, they might not have the specific understanding needed to make the most of CAD. To close this gap and enable professionals to successfully use CAD for creative water management solutions, educational institutions, and business leaders must work together to develop specialized training programs. CAD’s position in water management will continue to expand despite these obstacles as companies adapt and invest in technology and expertise, realizing its full potential in tackling the world’s water concerns.

Conclusion

In conclusion, CAD has revolutionized the design, optimization, and maintenance of water systems, having a significant impact on industrial water management. By reducing expenses and time consumption while enhancing precision and durability, CAD keeps expanding the realm of water infrastructure’s potential applications. As we look to the future, businesses like CAD Connect are leading the way in innovation. They are embracing cutting-edge technologies like AI and machine learning, integrating sophisticated simulations, and using CAD technology to support sustainable water use. These developments will open the door to water management strategies that are more effective and flexible. But the secret is to keep innovating. It is crucial to develop CAD tools and promote a culture of continuous development as the world’s water problems get more serious. We can guarantee a future where water systems are not just effective but also sustainable for future generations by pushing the boundaries of technology.

However, what is more important is partnering with the right partner to design the flawless water-tech infrastructure. Integrating CAD for building robust water-tech solutions with a sustainable outlook demands experience and expertise. CAD Connect, with a legacy of serving reliable solutions, from P&ID, 2D modelling, and 3D modelling to data sheets and concept design; we have your back for designing proficient infrastructure from scratch. Connect with us today and build your dream water-tech solution for a better tomorrow.