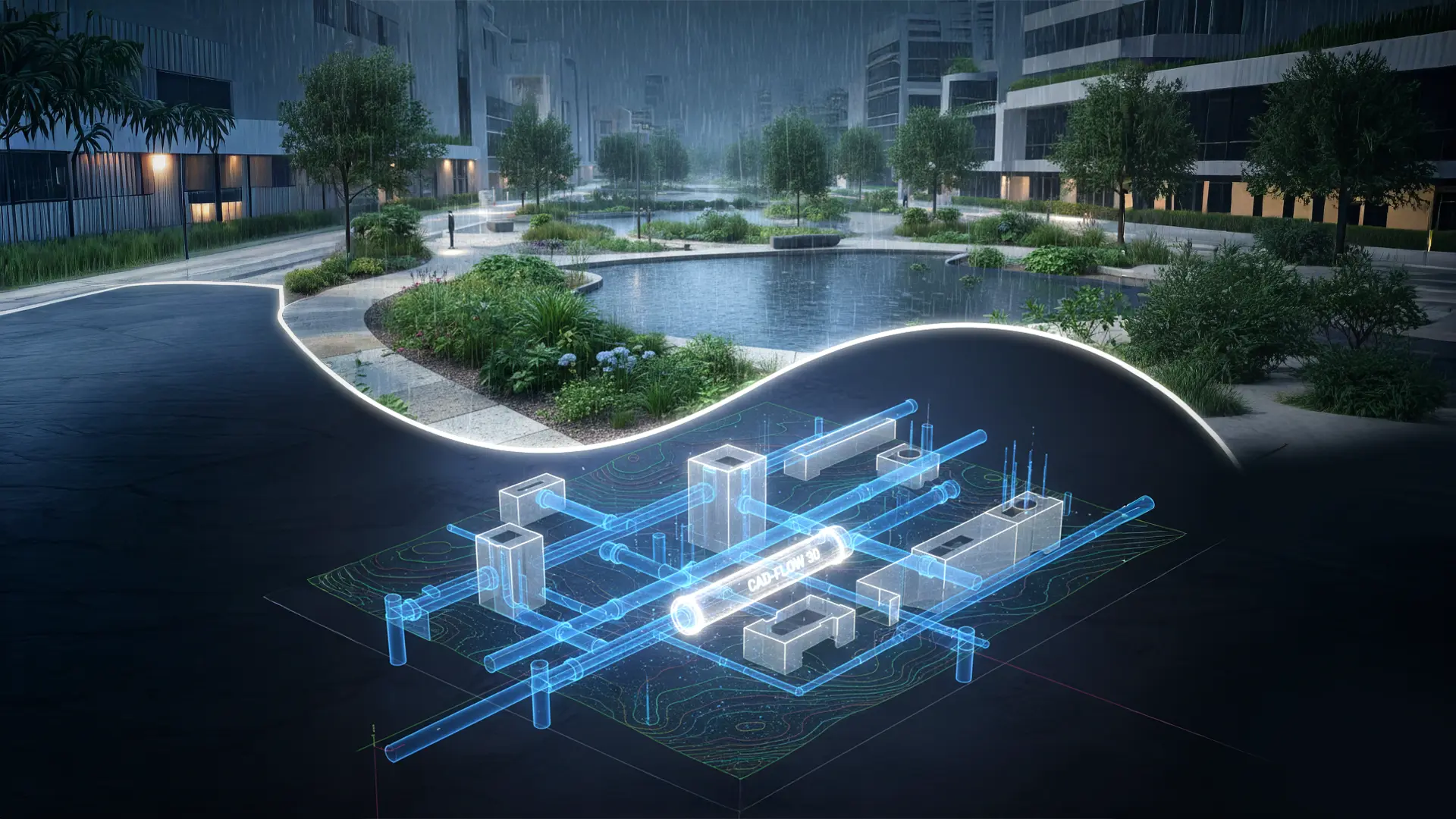

Reimagining Water Recycling With CAD-Driven Solutions for Tomorrow’s Challenges

Imagine you are living in the year 2070 and all you could hear in the news is the failure of water treatment infrastructure around the world. Nations struggle to build new infrastructure only to end up in more machine debris. This is not a science fiction story but a reality that we need to evaluate before it’s too late!

An article published by National Library of Medicine states that much of the United States’ drinking water distribution infrastructure has surpassed its intended lifespan and is now deteriorating. This deterioration poses growing challenges for maintaining a historically reliable water supply and ensuring protection against system contamination. Since much of this infrastructure was installed over 50 years ago, a significant portion may need to be replaced in the coming decades (AWWA 2012). Relying on CAD technology can help us assess the robustness of the infrastructure. The following article explains how CAD Driven solutions can improve the future of water recycling systems.

Overview of water recycling systems

Water recycling systems reduce the requirement for new water by processing wastewater and re– purposing it for numerous applications.

Gathering and Handling

Wastewater is obtained from residences, workplaces, and industries and treated in various phases. Sedimentation and screening are used in the main treatment to get rid of big particles and trash. Secondary treatment uses biological mechanisms to break down organic materials. By eliminating any remaining impurities from the water through filtration, disinfection, and other chemical treatments, tertiary treatment purifies the water. Before being used again, the treated water is kept in tanks or reservoirs for storage.

Types of Water Recycling Systems

Gray water systems recycle water from showers, sinks, and washing machines. They are typically used for irrigation, toilet flushing, and landscape maintenance.

Black water systems treat wastewater from kitchens and toilets, requiring more advanced treatment processes. The treated water can be repurposed for industrial processes and irrigation, aiding in sustainable water management and conservation.

Industrial water recycling is tailored for industrial processes, washing, and cooling. It helps industries reduce water consumption and discharge, promoting sustainable practices and lowering operational costs.

Municipal water recycling involves large-scale systems managed by communities or cities. These systems treat and supply water for industrial use, irrigation, and, after thorough treatment, can sometimes be used for drinking too.

Infrastructure Deterioration of Water Recycling Systems

Systems that recycle water are essential for managing water resources responsibly. They can be recycled for a variety of uses, such as irrigation, water supply, and industrial operations. Like any other infrastructure, water recycling systems can deteriorate over time. This can result in mismanagement issues, such as higher upkeep costs, decreased efficiency, and other potential health threats.

Causes of Deterioration

Listed below are the most probable reasons for deterioration of the water-tech infrastructure:

- Ageing infrastructure: It is the deterioration of materials used in the construction of tanks and pipes, which can result in splitting, corrosion, or silt obstructions. Over time, these materials degrade, compromising functionality and increasing the risk of failure. Mechanical components, such as valves and pumps, are particularly prone to wear and strain, resulting in malfunction or complete failure.

- Environmental factors: They have a substantial impact on the degradation of infrastructure. Corrosion can occur from chemical reactions between various compounds in water and the materials used to construct the infrastructure. Further, the flow of water can progressively erode the surfaces of pipes and tanks, particularly if the water contains abrasive particles. Additionally, the development of bacteria, algae, and other microorganisms within the system can cause blockages by clogging filters and pipes.

- Operating problems: Can emerge due to various circumstances, including the buildup of debris, biomaterials, and other blockages caused by improper maintenance methods. When a system is employed for tasks for which it was not designed, or when it gets utilized beyond its specified limitations, wear and tear can accelerate, causing premature failure. Furthermore, poor chemical treatment can cause severe damage to system components, sacrificing their functioning and durability.

Effects of Deterioration

- Decreased efficiency: This can lead to significant issues, such as water contamination resulting from the system’s inability to adequately clean the water. This compromised cleaning capability can pose serious health risks and reduce the quality of the recycled water. Additionally, lower output can occur when flow rates are reduced, and the system experiences extended downtime. This means that the quantity of recycled water available for use is limited, affecting supply and potentially increasing reliance on other water sources.

- Cost increases: Increase in overall cost in water recycling systems are often due to the need for more expensive and frequent repairs when unexpected breakdowns occur. As systems deteriorate, they typically require more energy to achieve the same outcome, leading to increased energy consumption. This raises operational costs and impacts the system’s efficiency and sustainability.

- Hazards to health: It can arise from poorly functioning water recycling systems that fail to adequately remove diseases and dangerous substances from the recycled water, leading to pollution. Such contamination poses significant health risks to the communities relying on this water. Furthermore, severe malfunctions in the system can result in service disruptions, impacting both businesses and residents in towns dependent on recycled water for their daily needs.

As mentioned in a case study published by WHO, titled “Application of a Predictive Model for Water Distribution System Risk Assessment in India”, risk due to contaminant ingress is determined by contaminant zones near leaky sewers and open drains and pipe condition, which is determined by the pipe condition assessment model. Accordingly, the relative risk ranks indicate that 3–4% of pipes fall in high to very high-risk categories. Approximately 6–7% of pipes are in the medium risk category and 89.7% are in the low-risk category.

Overcoming Infrastructure Deterioration in Water Recycling Systems using CAD Technology

Computer-Aided Design (CAD) technology can be a powerful tool in managing and mitigating the deterioration of water recycling systems.

Design and Simulation

Engineers can use CAD software to create detailed and comprehensive designs for water recycling systems. These plans can include all components like pumps, valves, tanks, pipes, and fittings, ensuring that each piece fits together correctly.

CAD software can simulate the complete system under various circumstances, even before any physical infrastructure is constructed or maintained. These aids in locating any problems, like weak spots or ineffectiveness, letting engineers to make modifications prior to building.

Maintenance and Upgrades

- As-Built Drawings: Accurate as-built drawings of the infrastructure that are in place can be produced using CAD software. These drawings offer an in-depth description of the system at the time of construction, which is vital for upkeep and upcoming modifications.

- Predictive maintenance: Engineers can forecast when and where maintenance will be required by combining data from sensors and monitoring systems with CAD models. This decreases downtime and helps avoid unanticipated failures.

Evaluation and Enhancement

- Structural Analysis: Various water recycling system components can be subjected to structural analysis using CAD software. Areas prone to erosion, corrosion, or mechanical failure can be found with this evaluation.

- Flow Simulation: Engineers can use CAD to simulate water flow through the system. This aids in optimizing the layout to ensure effective water distribution and treatment while reducing damage to the infrastructure.

Planning and Management

- Lifetime Management: To keep track of the age and component condition CAD models can relate to lifetime management software. It helps in methodically organizing upgrades and replacements.

- Scenario Planning: Using computer-aided design (CAD), engineers may create multiple scenarios and prepare for a range of unforeseen events, including natural disasters and rising water demands. This guarantees that the system will continue to be stable and dependable in many scenarios.

Training and Documentation

- Training Simulations: System maintenance and operators’ staff could profit from training simulations made with CAD models. They’re better able to understand the system and address issues because of this practical training.

- Extensive Documentation: Documents produced by CAD offer a clear and thorough explanation of the technology. Those consist of operation manuals, designs, and designs, maintenance schedules, all of which are essential to effective system management.

Examples for CAD Application

- 3D modelling: Building 3-D models of the water recycling system to examine and assess its elements.

- Finite Element Analysis (FEA): FEA is used to measure a material’s and component’s strength and durability under different conditions.

Integrating CAD and GIS to map out the system in relation to the environment is known as Geographic Information Systems (GIS) Integration. This is particularly important for large water recycling initiatives.

CAD technology offers a complete approach to the design, upkeep, and optimization of water recycling systems by utilizing computer-aided design (CAD), engineers can increase the dependability, lifespan, and efficiency of these vital infrastructures, ensuring a water management system that is sustainable.

Future trends in CAD for Water Recycling System Design:

Cloud-Based CAD

The efficient design of complex water recycling systems is made possible by cloud-based CAD tools, which enable smooth cooperation between engineers, designers, and stakeholders located in different places. Faster decision-making and improved project management are made possible by data exchange and real-time updates.

Generative Design

Using CAD generative design, many variations based on established criteria like material usage, cost, and performance may be explored. This can result in creative ideas for water recycling systems that improve resource efficiency and effectiveness of the system.

Virtual and Augmented Reality (VR/AR)

Immersion visualization and simulation of water recycling systems are made possible by the integration of VR and AR technologies with CAD. By allowing engineers to experience the design in a virtual setting, potential issues can be found and fixed easily prior to actual execution.

AI and Machine Learning Integration

By offering automated procedures, predictive analytic, and design optimization, AI and machine learning enhances CAD. Large-scale data analysis can be achieved with these technologies, which can be utilized to predict maintenance requirements, make design suggestions, and improve the performance of water recycling systems.

Conclusion

The integration of CAD-driven solutions into water recycling systems gives a promising space for addressing the water scarcity challenges of tomorrow. Through precise design, simulation, and optimization, CAD technology enables the creation of efficient and sustainable water recycling infrastructures. These cutting-edge technologies can guarantee a steady supply of clean water, minimize the impact on the environment, and greatly increase the efficiency of water reuse.

As we face the growing environmental Deterioration and increasing demand for water resources, embracing CAD-driven solutions is essential. By re-imagining water recycling through the lens of modern technology, we can build a resilient, sustainable and adaptable water system that will serve communities for generations to come. The future of water recycling lies in our ability to harness the power of CAD, driving progress and ensuring a more sustainable world.

However, what is more important is partnering with the right partner to design the flawless water-tech infrastructure. Integrating CAD for building robust water-tech solutions with a sustainable outlook demands experience and expertise. CAD Connect, with a legacy of serving reliable solutions, from P&ID, 2D modelling, 3D modelling to data sheets and concept design; we have your back for designing proficient infrastructure from the scratch. Connect with us today and build your dream water-tech solution for a better tomorrow.