Innovating Clean Water Access: CAD Solutions for Modular Purifiers in Developing Regions

Access to clean and safe drinking water remains a pressing issue in many developing regions. Communities often struggle with contaminated sources, inadequate infrastructure, and limited resources to implement conventional water treatment solutions. In this context, modular water purifiers present a practical and scalable alternative. When combined with Computer-Aided Design (CAD) technology, the development of these systems becomes more efficient, precise, and adaptable. This article explores the challenges and opportunities in designing modular water purifiers using CAD tools, especially for low-resource settings, and how companies like CAD Connect support innovation in this field.

Understanding Modular Water Purifiers

Modular water purifiers are composed of separate, interchangeable units—such as sediment filters, carbon cartridges, and UV disinfection components—that can be easily assembled, replaced, or upgraded. This modular approach offers flexibility and simplifies maintenance, making it especially suitable for remote or underserved areas with limited infrastructure. These systems can be adapted to various water quality conditions and usage scenarios, ensuring that each community gets a purifier tailored to their specific needs.

The modular design also supports scalability: from compact units for households to larger systems for community use. This makes it a practical solution across a wide range of geographic and socio-economic settings.

The Role of CAD in Modular Design

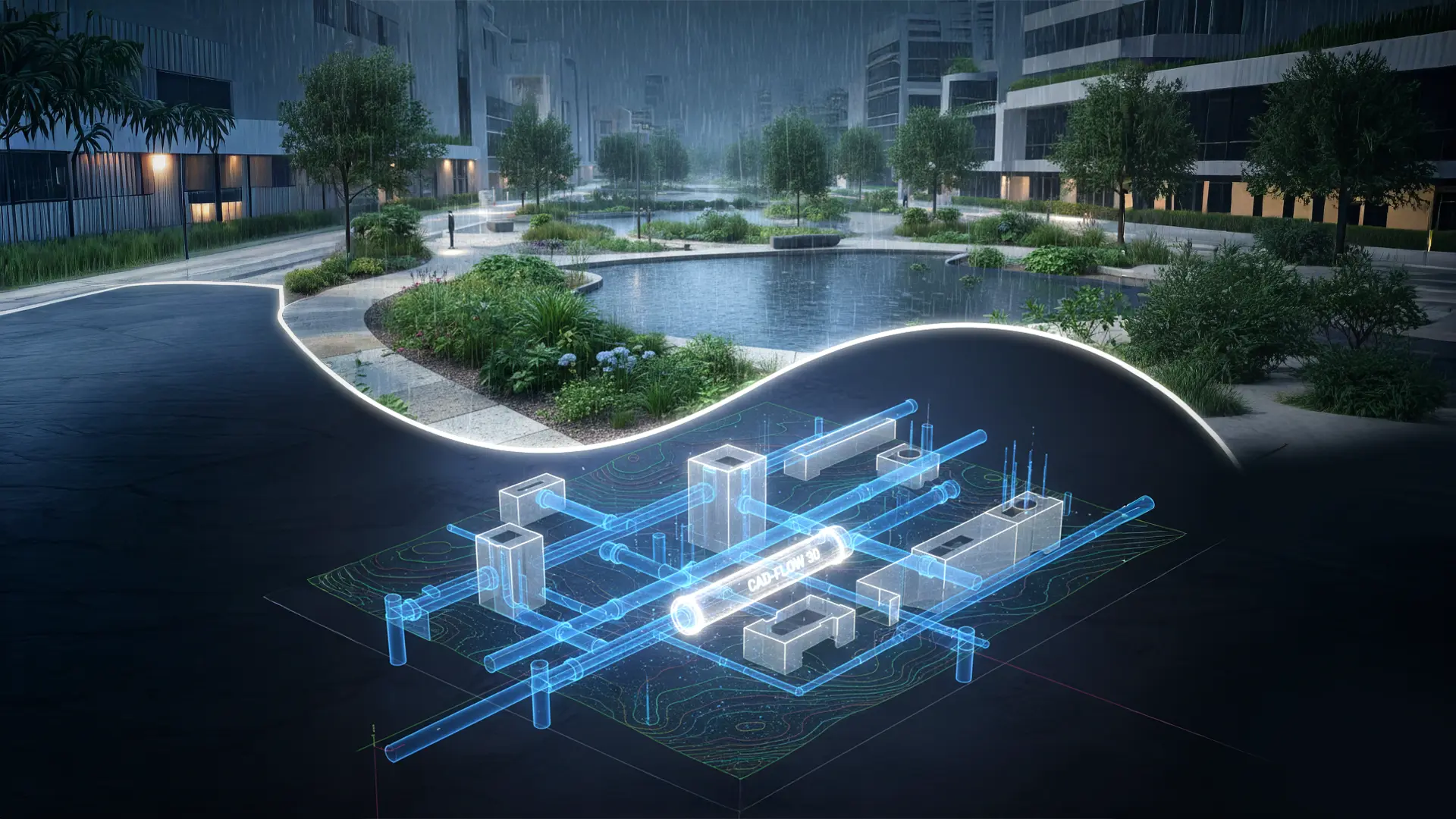

Computer-Aided Design (CAD) software allows engineers to conceptualize, simulate, and refine water purifier components and systems in a virtual environment. This digital approach significantly reduces prototyping costs and development time while enhancing accuracy.

Through CAD, designers can create detailed 3D models of modular systems, allowing for better visualization and testing. It enables seamless integration of various modules, ensuring compatibility and ease of assembly. With simulation tools embedded in many CAD platforms, designers can assess water flow rates, pressure loss, and filtration efficiency before manufacturing begins.

CAD Connect, a leader in advanced CAD services, supports designers and engineers in developing modular water purification systems tailored for challenging environments. From precision design to virtual testing, CAD Connect’s expertise ensures that purification systems are functional, durable, and user-centric.

Key Challenges in Designing Modular Water Purifiers

Despite the many advantages, several challenges arise when designing modular water purifiers for developing regions.

- Cost Constraints: Affordability is a critical factor. The design must ensure that the system remains within the financial reach of low-income users while still meeting essential health and safety standards. This calls for strategic material selection and minimalistic, yet effective, design practices—an area where CAD tools provide considerable support.

- Cost Constraints: Affordability is a critical factor. The design must ensure that the system remains within the financial reach of low-income users while still meeting essential health and safety standards. This calls for strategic material selection and minimalistic, yet effective, design practices—an area where CAD tools provide considerable support.

- Limited Access to Advanced Manufacturing: Many target regions lack the infrastructure to produce high-tech components. This necessitates a design philosophy centered around simplicity, utilizing locally available materials and production methods. CAD can simulate the use of these materials, ensuring durability and compatibility.

- Environmental Durability: Purifiers in rural or off-grid regions often face extreme conditions such as heat, humidity, and dust. Designing for resilience under these environmental stressors is crucial. CAD helps simulate these conditions, allowing engineers to make informed design decisions without costly field trials.

- User-Friendliness: Users in these regions may not have technical backgrounds, so systems must be intuitive to assemble, use, and repair. CAD allows designers to develop and visualize ergonomic features, simple interfaces, and clear assembly instructions, improving usability.

- Supply Chain and Logistics: Ensuring the availability of replacement parts is a persistent challenge. Modular systems must be standardized to allow parts to be interchangeable and easily sourced. CAD enables the precise definition of dimensions and tolerances, facilitating localized or distributed manufacturing.

- Variability in Water Quality: Water contamination varies greatly between locations. A modular system must be adaptable, capable of incorporating specific filtration technologies based on local water analysis. CAD makes it easier to create customizable components that fit into a standardized core structure.

Opportunities Enabled by CAD

While the challenges are considerable, CAD technology unlocks a wide range of opportunities that can accelerate progress in clean water access.

Open-Source and Collaborative Design

With CAD, design files can be shared openly across regions, allowing engineers to build upon one another’s work. This collaborative ecosystem promotes faster innovation and local customization. CAD Connect encourages this model by offering design services that are flexible and easily adaptable for different contexts.

Rapid Prototyping and Local Manufacturing

CAD models can be directly used with 3D printers or CNC machines, enabling local manufacturing and reducing reliance on distant supply chains. This supports faster deployment and easier maintenance, especially when paired with decentralized production strategies.

Scalability and Flexibility

CAD allows for the development of modular systems that can be scaled or adapted to different population sizes and usage conditions. Whether it’s a single-family home or an entire village, designers can tailor the size and capacity of the purifier using the same base framework.

Simulation and Optimization

Advanced CAD platforms allow for fluid dynamics simulations, helping designers optimize water flow, pressure, and filtration efficiency. This means, design flaws can be identified early, reducing development costs and improving overall performance.

Education and Capacity Building

CAD-based design can be part of educational initiatives, empowering local engineers and technicians to develop and maintain their water purification systems. By offering modular, easy-to-adapt CAD templates, organizations can support skill development and local innovation.

Sustainable Design Integration

CAD tools also support the integration of sustainable design principles. Engineers can evaluate the environmental impact of materials, energy use, and lifecycle performance. Designing purifiers that are energy-independent via solar modules or manual pumps can be seamlessly incorporated into CAD workflows, ensuring off-grid functionality.

Designing modular water purifiers using CAD tools presents a compelling opportunity to address the global water crisis in developing regions. Though there are clear challenges- ranging from affordability to environmental resilience, the potential for scalable, locally manufactured, and customizable solutions is vast. CAD Connect plays a vital role in enabling modular water purification innovation. By offering specialized CAD services for product design, simulation, and optimization, CAD Connect helps organizations develop reliable and efficient purifier systems. From initial concept modeling to final system layout, CAD Connect ensures precision, adaptability, and user-oriented solutions. The company’s commitment to sustainable, affordable engineering design makes it a trusted partner for projects targeting water access in underserved regions.

Reach out to CAD Connect today to learn how we can help you in designing your future modular water purifier projects.