How CAD Technology Transforms Biogas Plants into Water Recovery Powerhouses

As sustainability becomes a global priority, biogas plants are playing an increasingly important role in renewable energy strategies. By converting organic waste into usable gas, these systems support waste reduction and energy independence. Many modern facilities now integrate water recovery systems to conserve freshwater and reduce wastewater discharge, enhancing both environmental and operational outcomes.

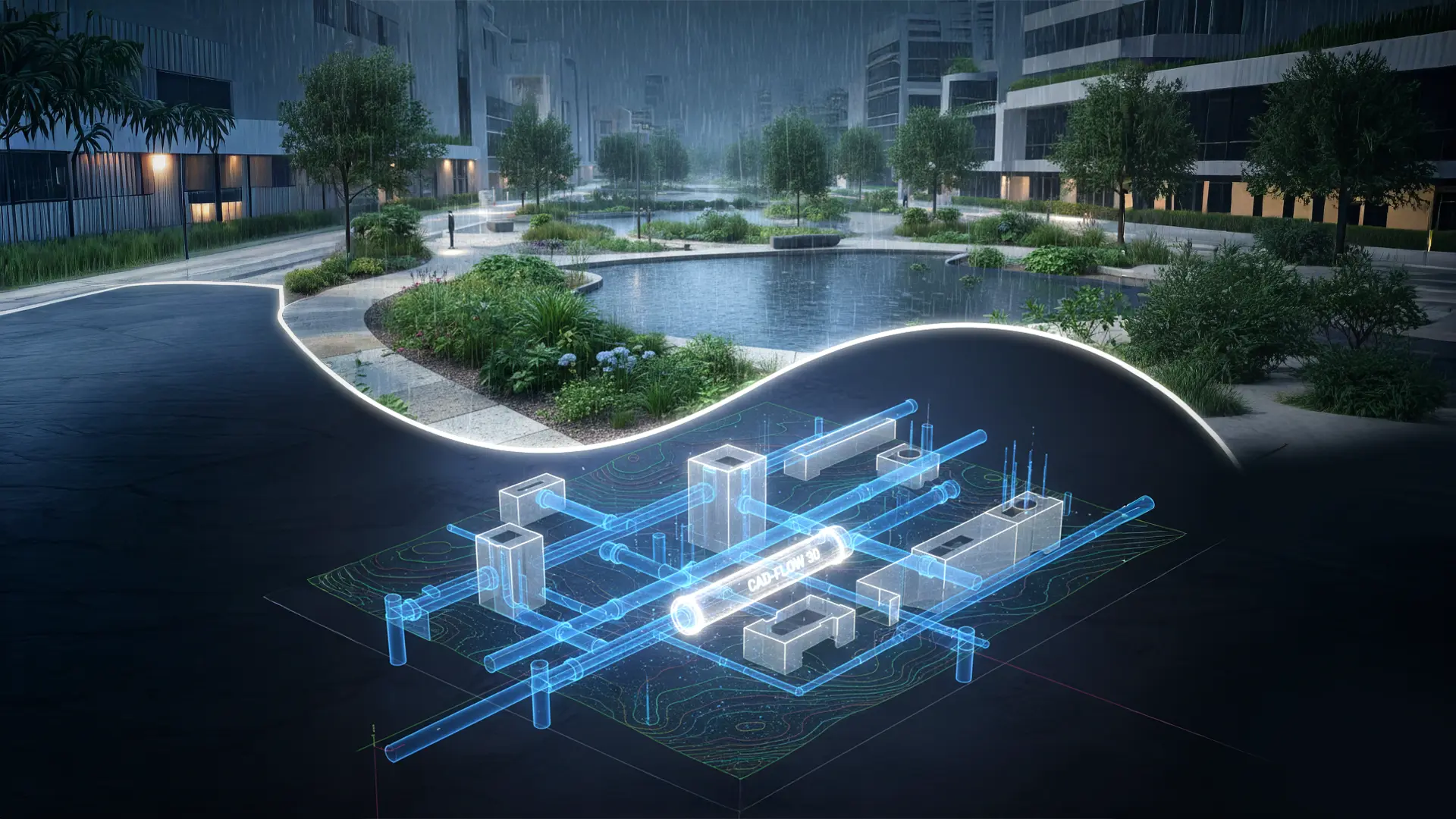

However, this dual-function integration introduces complex design and engineering challenges. To address these effectively, Computer-Aided Design (CAD) tools have become essential. They allow engineers to visualize, simulate, and optimize biogas plant systems in ways that traditional methods cannot match.

The Rise of Integrated Biogas Systems

Modern biogas infrastructure is evolving beyond single-purpose plants. By including wastewater reuse and resource recovery, designers can create multi-functional systems that maximize output while minimizing environmental impact.

Yet, integrating these systems adds layers of complexity. Engineers must account for space limitations, material selection, process synchronization, and compliance, all while ensuring the design remains cost-effective and efficient.

Key Design Challenges

- Efficient Use of Space: Many biogas facilities are built in areas with limited land availability. Adding water treatment units, storage tanks, and piping networks within this tight footprint can quickly become a logistical problem. Without careful planning, the layout may compromise accessibility and operational flow.

- Coordination Between Processes: Biogas digestion and water recovery operate on different process cycles. Synchronizing their flows without creating backups, delays, or downtime requires careful planning and flow analysis.

- Material Compatibility: Corrosive slurries, variable temperatures, and high moisture levels demand robust material choices. Selecting the wrong materials for tanks, valves, and connectors can lead to frequent breakdowns, increased maintenance, and system failures.

- Thermal Interference: While digesters require stable temperatures, water recovery processes may release or absorb heat. If not managed well, this thermal interference can reduce process efficiency or even damage sensitive components.

- Regulatory Compliance: Biogas plants must meet environmental standards for emissions, wastewater discharge, and worker safety. Integrating multiple systems increases the documentation and certification burden for regulatory approval.

- Maintenance Access: With compact, multi-functional layouts, routine maintenance can become a challenge. Designers must ensure easy access to pumps, valves, and tanks without halting operations.

How CAD Tools Solve These Challenges

- 3D Modelling for Layout Planning: With CAD software, engineers can create detailed 3D models of the entire facility. This allows visualization of all components, ensuring efficient placement and reducing the risk of design clashes. Tight spaces can be optimized before construction begins.

- Process Simulation and Flow Design: Modern CAD platforms incorporate simulation tools that allow testing of fluid flow, pressure loss, and system timing. This makes it easier to align the performance of water recovery units with gas production systems, improving reliability and output.

- Material Analysis and Selection: Engineers can use CAD to simulate real-world conditions such as load-bearing stress, vibration, and chemical corrosion. This data helps select appropriate materials for every part of the system, improving longevity and reducing lifecycle costs.

- Thermal Mapping and Insulation Design: Thermal simulation features in CAD tools help identify heat zones, allowing for better planning of insulation and cooling systems. This ensures both digestion and water recovery operate within optimal temperature ranges.

- Compliance Documentation: CAD software can generate technical drawings, P&ID diagrams, and safety plans in accordance with industry standards. This streamlines regulatory submissions and helps ensure code compliance from the earliest design phase.

- Designing for Maintainability: Virtual walk-throughs and accessibility checks within the CAD model allow teams to ensure that all components remain accessible for inspection, cleaning, and repair. This reduces downtime and improves plant reliability over time.

Benefits of Using CAD in Integrated Biogas Design

- Continuous Design Optimization: CAD tools support rapid iteration and experimentation. Engineers can test alternative layouts, materials, and flow designs in a virtual environment before implementation. This reduces costly on-site modifications and improves performance.

- Digital Twins and Predictive Analysis: Advanced CAD models can be turned into digital twins real-time, data-driven replicas of the physical plant. These twins simulate operating conditions, predict failure points, and optimize performance based on sensor feedback.

- Cost and Resource Efficiency: Precise CAD modelling helps minimize material waste, reduce construction rework, and optimize component sizing. For example, correctly sizing pumps or heaters using CAD can cut energy use and operating costs.

- Water Savings and Revenue Opportunities: Designing efficient water recovery through CAD reduces the need for fresh water and minimizes wastewater disposal costs. Treated water can be reused for irrigation, cooling, or industrial cleaning, opening additional revenue streams.

Future Trends in CAD for Biogas Plants

AI-Driven Optimization: Modern CAD tools are integrating AI algorithms to automatically suggest optimal layouts, flow paths, and component selections based on performance data.

BIM Integration: Building Information Modelling (BIM) enhances collaboration by providing data-rich 3D models that cover the plant’s entire lifecycle from design and construction to operations and decommissioning.

Cloud-Based Collaboration: Cloud- based CAD platforms enable real-time collaboration between multidisciplinary teams. This is particularly useful for international projects with remote stakeholders.

Embedded Sustainability Metrics: Emerging CAD software includes carbon footprint calculators, energy efficiency tools, and sustainability scoring helping engineers design with environmental impact in mind from the start.

The integration of water recovery systems into biogas plants is a forward-thinking approach to sustainability, but it introduces significant complexity. From spatial planning to thermal control, every aspect of the design must be carefully balanced to ensure reliable operation and regulatory compliance.

CAD tools provide the digital foundation needed to tackle these challenges. By enabling simulation, optimization, and collaboration, CAD empowers engineers to design smarter, more efficient, and environmentally responsible systems.

As demand grows for integrated, sustainable infrastructure, CAD will continue to play a central role in shaping the future of industrial plant design, making it not just a tool but a critical driver of innovation. CAD Connect, a pioneer in designing sustainable CAD solutions, has been dedicatedly serving customers with cost-efficient design solutions. Connect with us and transform your vision into reality.