How CAD Innovation Slashes Waste in Modular Water Purification Systems

Imagine a water purifier that fits in a shipping container, serves entire communities, and leaves behind almost no waste. Sounds futuristic? Not anymore. Modular water purification units are redefining how we deliver clean water to remote, urban, and crisis-hit areas. But their real potential isn’t just in portability! It’s in how smartly they manage waste. Behind the scenes, Computer-Aided Design (CAD) acts as the digital brain, helping engineers simulate, refine, and reduce waste at every stage of the system’s lifecycle. In this blog, CAD Connect explores how design innovations and CAD-driven engineering are making these units more efficient and environmentally responsible.

Overview of Modular Water Purification Units

Modular water purification units are prefabricated, scalable systems designed to provide safe, reliable, and flexible water treatment solutions for potable and domestic use as well as wastewater treatment. These units are advantageous due to their ease of deployment, customization, and sustainability in various contexts including emergencies, remote areas, and industrial applications.

Key Features and Technologies

Multi-stage treatment processes: These may include filtration (e.g., disc filters, activated carbon filters), reverse osmosis, UV disinfection, iron removal, chemical dosing, and aeration to ensure the removal of pathogens, chemicals, and particulates.

Scalability and customization: Modules can be combined or expanded to match the treatment capacity required for small communities, industrial facilities, or emergency relief operations.

Pre-fabrication and standardized production: Units are often manufactured in controlled environments, such as ISO-certified facilities, ensuring quality, ease of installation, and shorter project timelines.

Portability and rapid deployment: Many systems are containerized or skid-mounted, enabling quick transport and setup in locations lacking permanent infrastructure, such as disaster zones or remote areas.

Advanced monitoring and operation: Modern systems include remote telemetry and automation for operational oversight and timely maintenance.

Sources of Waste in Modular Water Purification Units

Modular water purification units generate waste from multiple sources during their operation, primarily involving solid, liquid, chemical, and gaseous byproducts. Understanding these sources helps in managing waste effectively and ensuring environmental compliance.

Solid Waste

Sludge: A common byproduct from various treatment stages, especially from coagulation, flocculation, sedimentation, biological treatment, and filtration. This includes primary sludge from sedimentation and secondary sludge from biological processes. Sludge is often dewatered and treated before disposal or reuse.

Filter Media Residues: Waste materials from filters like activated carbon, sand, or membrane elements accumulate contaminants and are periodically replaced or cleaned; residues from these can become solid waste.

Organic Waste: Some modular systems incorporate the processing of organic food and fecal waste, generating solids that are further treated in anaerobic or aerobic bioreactors, yielding stabilized biosolids and biogas.

Liquid Waste

Wastewater Streams: Concentrate or brine from reverse osmosis units is a liquid waste stream rich in salts, chemicals, and contaminants not passed through the membrane. This reject water requires careful disposal or reuse strategies.

Backwash Water: Backwashing processes in media filters (e.g., sand or carbon) flush trapped particles to clean the media, generating liquid waste that contains suspended solids and chemical residues.

Chemical Wastewater: Liquid waste containing dosing chemicals (e.g., iron salts, coagulants, disinfectants) or residuals from chemical precipitation can be generated, necessitating controlled handling to avoid environmental damage.

Chemical Waste

Spent Chemical Solutions: Chemicals used for phosphate removal, disinfection, pH adjustment, and scale inhibition may produce waste streams and subsequent precipitates and sludge containing heavy metals or other reagents.

Excess Chemical Dosage: Overdosing chemicals due to improper control or maintenance errors can increase chemical residues in waste streams, affecting sludge composition and disposal requirements.

Design Innovations for Waste Reduction

Advanced PFAS Destruction Technologies

New electrochemical advanced oxidation processes use patented diamond electrodes to break down persistent compounds such as PFAS at the molecular level, preventing chemical concentration and reducing hazardous waste. These technologies also achieve up to 75% energy savings compared to conventional methods and eliminate the need for chemical additives, supporting ecological and economic benefits.

Bio electrochemical Treatment Systems

Modular Bio electrochemical reactors use microbes to consume organic pollutants while simultaneously generating electricity, achieving significant greenhouse gas reductions (up to 90%) and reducing sludge and chemical waste.

Membrane Filtration Enhancements

New membrane materials designed with uniform pore distribution and antifouling properties improve filtering efficiency and durability, thereby reducing membrane replacement frequency and associated waste.

Containerized and Prefabricated Systems

Prefabricated containerized treatment units reduce on-site construction waste, accelerate deployment, and enable reuse of entire units across sites, cutting material wastage and operational downtime.

Energy-efficient Design

Innovations include integration of low-power pumps, hybrid renewable energy sources, and optimized aeration techniques to reduce operational energy consumption and related indirect waste generation.

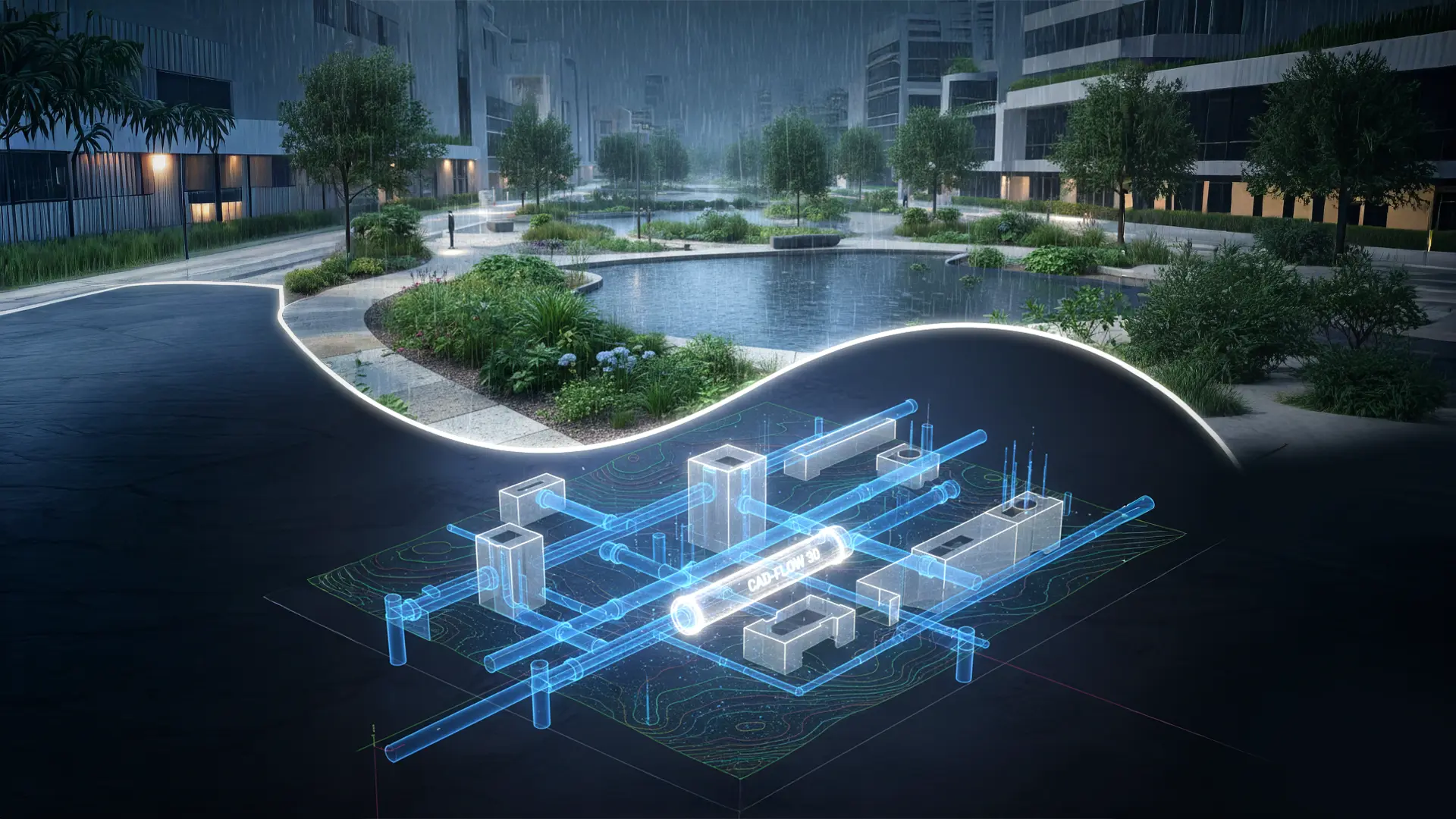

Precision Modeling & Process Simulation

CAD enables detailed 3D modeling of treatment components and layouts while supporting integrated simulations for fluid dynamics, chemical dosing, and contaminant behavior. This ensures accurate system design and performance forecasting, reducing material waste and costly errors.

Virtual Prototyping & Design Optimization

Through virtual testing and rapid iteration, CAD minimizes the need for physical prototypes. Engineers can refine layouts and system parameters digitally, significantly cutting development time, cost, and material use.

Customization & Sustainable Design

CAD allows designers to tailor purification units to specific site requirements—balancing water quality, volume, and operational conditions, while also supporting lifecycle assessments to lower energy and chemical footprints.

Integrated Collaboration & Smart Technology

Modern CAD platforms enable real-time collaboration, version control, and documentation, while integrating with AI, IoT, and cloud tools. This fusion supports predictive maintenance, automated adjustments, and data-driven decision-making for efficient, waste-reducing designs.

Computer-aided design (CAD) is the cornerstone of modern modular water purification, empowering engineers to optimize layouts and processes virtually reduc

ing physical prototypes by 50%, and cutting prototyping costs by 48%. Startups like CAD Connect leverage these advantages through a full suite of CAD services: 2D drafting, 3D modeling, FEA, and data management—ensuring every purification unit is designed with maximum precision, efficiency, and sustainability in mind. Contact us today to discover how CAD Connect can transform your next water purification project: