Design for manufacturing

The internet has no shortage of designer vs engineer or architect vs engineer jokes. Designers are often depicted as leaping for the stars and engineers are shown complaining about fuel and thrust concerns. Designing for manufacturing and assembly is a design principle or a design goal that requires both the designer brain and the engineer brain to work together. The goal of DFM is to consider the manufacturing and assembly processes during the design phase and design a product that is easy to produce in bulk.

Designing a product is a complex process. Many factors come into play here, from aesthetics to functionality. And the design process can go anywhere from 3 months to 5 years(or more). The manufacturability of a design is an important aspect of this design process.

What is design for manufacturing or DFM?

Design for manufacturing is a practice to make your product easy and cost-effective to manufacture and assemble using available materials and machinery. DFM takes into account factors other than form and function. A good product design will be aesthetically pleasing to look at and will perform as intended. But to scale up and produce in bulk, the product must be designed for manufacturing.

A major goal of designing for manufacturing is to keep the costs down. And it can go sky high if you don’t consider the manufacturing process early in the product design process. During the design phase, a high cost for a prototype is acceptable. But when manufacturing in bulk, if the cost per unit is too steep, the profit margins will take a hit.

And changes further down the design process is costly. If you can manufacture the product with existing machinery and tooling, you can bring down the cost dramatically.

In the past, DFM techniques also had to take into account the tools available. With current manufacturing technologies, it is possible to manufacture just about everything. Additive manufacturing and robotic assembly can manufacture products without specific tooling. But constraints like cost and time still apply. Even if we’re using advanced additive manufacturing techniques or robotic assembly there are guidelines and practices to be followed for efficient manufacturing.

What is the need for design for manufacturing?

As discussed above, the main goal of DFM is to keep the production costs down. As the product design evolves through the process, it undergoes various changes.

Imagine you’re designing an enclosure for an electronic device. You might change the external appearance based on recommendations from the marketing team. The size may change to accommodate internal components and for proper ventilation. Changes made for ergonomics may affect the internal layout necessitating further changes.

And the final product will be an amalgamation of all of these interconnected decisions. You will send the finalized product design to the manufacturing division. They inform you have to make some minor corrections or changes for making it in bulk. Then the whole process goes all over again. Or they inform you that the manufacturing cost is prohibitively expensive.

By incorporating DFM techniques into your design process, you can avoid this problem.

Important factors in design for manufacturing

The factors that play into designing for manufacturing are not the same for all products or manufacturing processes. For example, when you’re designing for 3D printing, if you can minimise the support structures required, you can reduce the post-processing time. Similarly, when building something for CNC machining, you can reduce the time required if you can reduce the number of flips.

Most manufacturing processes are automated, and the goal is to make the entire process automated. So by keeping automation in mind, you can come up with some general ideas for designing for manufacturing and assembly.

Design for the available equipment

As discussed above, designing for manufacture differs according to the equipment. And for best results, always consider how you’ll be manufacturing, even in the first few drafts.

But also, design for the existing equipment. If your organisation has invested in a set of equipment or has a manufacturing facility, you can cut down the cost significantly by designing for them. And if not, design for machinery easily available. Exotic designs that require specialised equipment can drive up the manufacturing cost. And this equipment may be useless once the production run is over. Or the product is discontinued.

Reduce equipment changes

By running most of the process in a single piece of equipment you can reduce the production time. Shifting between multiple pieces of equipment takes time. You have to align the piece and load it correctly onto the equipment. This is the same reason why you have to reduce the number of flips while using a CNC machine. Every time the piece is moved, it has to be loaded correctly. If the process uses jigs, the equipment has to be attached correctly.

You waste time and resources every time you move a piece from equipment to equipment.

Reduce the variations

When you have different models of the same product, you’ll have to change the production methods accordingly. This will drive up the cost of production. When you’re developing multiple versions or variants of the product, there will be differences among them.

But by maintaining the design as consistent as possible, you can use similar machinery and process for the variants. And this will bring the cost down.

A great example is the battery pack on Tesla Model S cars. There are two different variants, Model S 70 with a 70kWh battery and a Model S 75K with a 75kWh battery. But the fun fact here is that both cars have the same battery. In the Model S 70 variant, the additional 5kWh is locked out for users through software. Putting the same battery reduces the manufacturing cost, but the company is still able to roll out two variants at different price points to the customer. And customers can later upgrade their batteries through a software update by paying an additional amount.

And if the differences are huge, make it modular

Sometimes for complicated products, there will be sufficient differences between variants that you cannot ignore. In a modular design, the assembly process will simply pick the correct modules and bring them together to create a specific variant. By building as modules, common parts for all the variants can be manufactured through the same process. And when all the modules fit well with each other, they can also be assembled through the same process with minor differences.

This is something you can often see in vehicles. The chassis of all the variants of the same car will be the same. Some variants may have alloy wheels, some may have a different infotainment system, and some may have more features. The assembly team(or equipment) will use the relevant parts for the specific variant.

And as you may know, Ikea has made a business out of this.

Go for the loosest tolerances possible

Tolerance analysis plays a huge role while designing for manufacturing. Tighter the tolerance, higher the cost of equipment, higher the quality control requirements, and in general, higher the cost of production. A worst-case analysis can drive up the tolerance requirements. With statistical tolerance analysis techniques, you can create good designs that work, without driving up the cost of production.

Most importantly involve diverse people in your design team.

The best way to design for manufacturing is to bring people of different backgrounds into your team. The team will design a product to look good, work properly, and get the proper certifications. But the manufacturing part is at the very end. And teams often pay little attention to it in the early stages. By bringing in production experts to your team, you’re bringing manufacturing and assembly way early into the design process. You can reduce or avoid the changes later in the process to better suit manufacturing.

Of course, this doesn’t apply to just the manufacturing part, involving diverse people will improve your design process in all manner of ways.

Latest trends in design for manufacturing

It’s safe to say that advances in design technologies have an almost direct impact on designing for manufacturing. The goal of every new technology or software in design is to reduce the time between the first draft and the production run. Designers and other stakeholders are well aware of the bottle-necks at the manufacturing stage when it is not accounted for during the design.

Here are a couple of technologies that are changing the design process and the role they play in designing for manufacturing

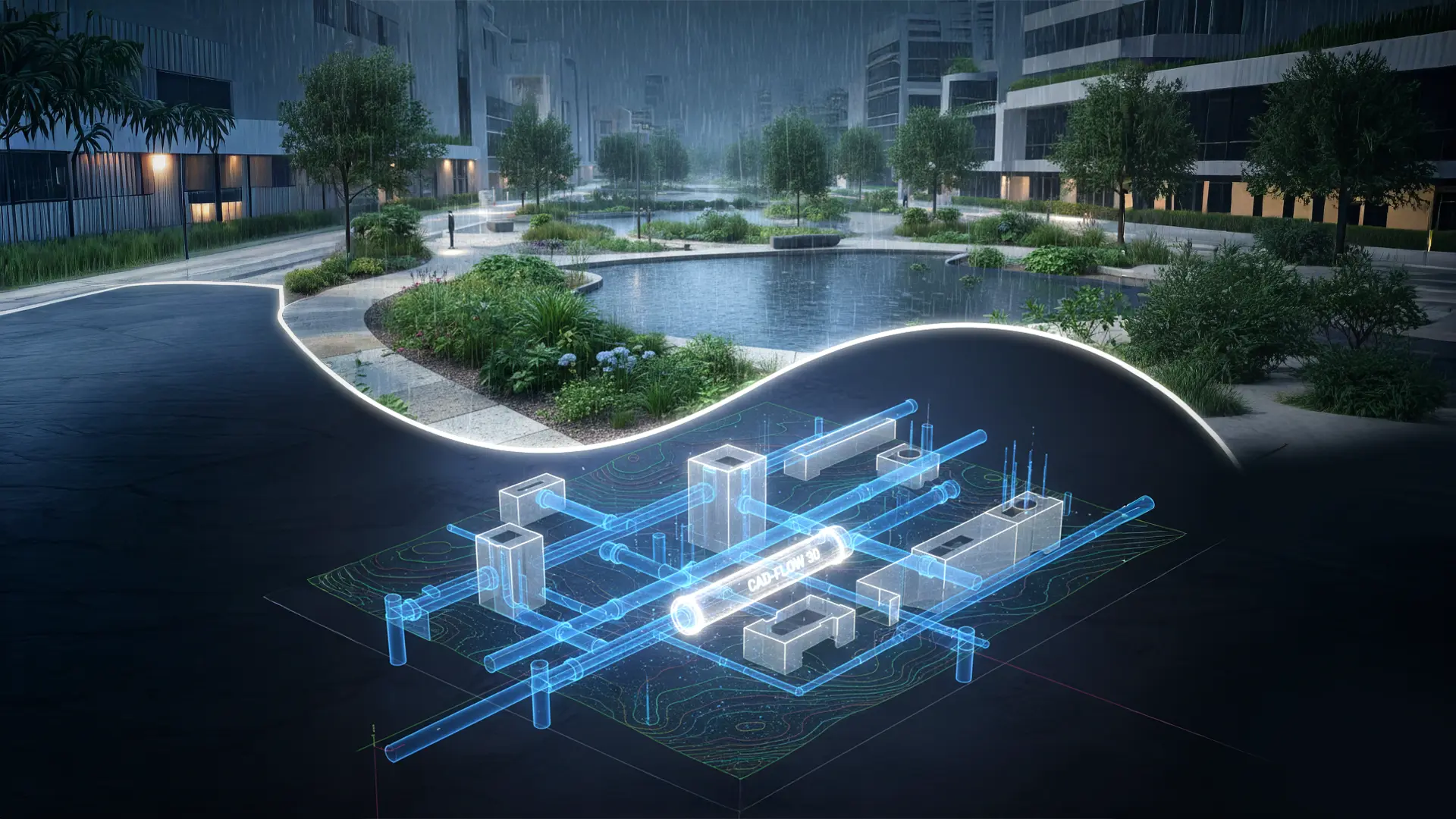

AR and VR and their role in design for manufacture

Augmented reality and virtual reality is yet to gain traction as consumer technology. But they have already found many applications in design. Many design studios extensively use AR and VR in their design process. As you can imagine, being able to see a product fully formed even before the prototype makes the entire process much faster. You can place the design, see how it looks, and even how it works before you make it. For example, if you’re designing a lamp, you can see how it will look on a desktop while designing it.

An overlooked benefit is the ability to collaborate better. Instead of standing hunched around a monitor, the entire team can put on the glasses and view the design as it develops. And make changes as necessary. And the production experts can point out any issues during the first draft itself.

Additive manufacturing

Additive manufacturing, or 3D printing technologies as they are commonly called, have now become part of manufacturing processes and are not just limited to creating a prototype. These technologies have earlier fast-tracked product design through rapid prototyping.

But with their entry to full-scale manufacturing, they’ve reduced the need for specialized tooling and equipment to a large extent. A single machine can produce all kinds of parts and products. And when 3D printing reduced the need for specialised tooling, it brought out possibilities to manufacture complicated designs with fewer constraints. There’s more freedom to design without worrying about the cost of tooling for large scale manufacturing.

But this doesn’t eliminate the need for designing for manufacturing and assembly. It simply changes to accommodate the specifics of 3D printing.

Automation is the name of the game in DFM

Most of the manufacturing facilities around the world use automation to some extent. As technologies like AI and robotics grow, automation is only going to grow. And become more flexible.

In the past, designing for manufacturing meant designing for maximum automated production, running the production line with the least human intervention. The goal was to achieve this along with minimal cost. But the technology wasn’t perfect, and you couldn’t automatically manufacture any design you wanted. But with advances in technology and the arrival of further smart manufacturing technologies, machines will be able to produce complicated products without staggering production costs