Breakthrough CAD Methods for Maximum Biogas Plant Efficiency

What if the secret to biogas plant success isn’t about the feedstock, it’s about mastering the invisible forces of heat and water flow?

While everyone focuses on turning organic waste into clean energy and digestate, the real game-changers understand this: your plant’s performance lives or dies by how brilliantly it manages internal thermal and hydraulic systems. The anaerobic digestion process demands rock-solid temperature stability: 30–40°C (mesophilic) or 50–60°C (thermophilic); to keep microbial activity thriving. Even slight fluctuations will crush gas yields and devastate your microscopic workforce.

Water plays an equally critical role, diluting feedstock, transporting slurry, cooling mechanical systems, and enabling essential cleaning operations. This is where smart design and CAD technology become game-changers, allowing engineers to model optimal heat exchangers, map thermal flows, and design integrated recovery systems that turn waste heat into operational gold.

Mismanagement of either resource triggers brutal consequences: energy demands spike, digestion fails, equipment suffers, and wastewater generation explodes. But with optimized heat and water exchange through integrated strategies and automation, plants can stabilize processes, boost biogas output, slash costs, and dramatically improve sustainability.

.

How Can Heat and Water Be Managed Efficiently?

Effective management of heat and water begins with recovery, reuse, and smart system integration. Heat generated by various components within the plant can often be harnessed and redirected to maintain digester temperatures.

Combined Heat and Power (CHP) Units: These systems produce electricity and generate waste heat, which can be captured and reused for heat digesters.

Exhaust Gas Recovery: Hot exhaust gases from engines or generators can be passed through heat exchangers to preheat incoming feedstock.

Engine Cooling Systems: The coolant used in engines absorbs heat, which can then be used in thermal loops within the plant.

Pasteurization Units: Often necessary for sanitizing digestate, these can be integrated into the thermal network for maximum efficiency.

On the water side, the following strategies can dramatically improve sustainability and efficiency:

Process Water Recycling: Treated effluent water can be filtered and reused for feedstock dilution or cleaning, reducing freshwater intake.

Rainwater Harvesting: Capturing rainwater for operational use helps conserve local water resources.

Condensate Recovery: Steam or vapor generated during biogas cooling can be condensed and reused.

Flow Monitoring Systems: Sensors can track water use and detect leaks or inefficiencies in the system.

An integrated approach combining heat and water management into a unified system yields the most benefits. For example, hot water from CHP units can be used both for heating digesters and for cleaning purposes, effectively serving dual roles with minimal waste.

Advantages of Optimizing Heat and Water Exchange

Optimizing heat and water exchange in biogas plants brings measurable benefits across technical, economic, and environmental dimensions:

Reduced Operational Costs: Reusing heat and recycled water minimizes fuel and water purchases, directly reducing operating expenses.

Lower Energy Demand: Efficient insulation and targeted heat recovery reduce the external energy required for heating.

Enhanced Biogas Production: Stable and controlled conditions foster ideal microbial activity, leading to higher biogas yields.

Decreased Environmental Footprint: By conserving water and reducing emissions from excess fuel burning, plants contribute less to local and global environmental degradation.

Improved Process Reliability: Consistent thermal and hydraulic conditions prevent system shocks, equipment wear, and microbial imbalances.

These advantages also make the plant more attractive to investors, regulators, and communities looking for sustainable and responsible energy solutions.

Challenges and Considerations

Despite the clear benefits, several challenges can hinder the effective optimization of heat and water systems:

Initial Investment: Advanced equipment such as heat exchangers, condensate recovery units, and high-efficiency filters can involve significant upfront costs.

System Complexity: Integrating thermal and water networks requires detailed planning and precision engineering, making retrofitting existing plants more difficult.

Operational Expertise: Skilled personnel are necessary to manage and maintain sophisticated recovery systems and automation tools.

Regulatory Compliance: Plants may face limitations or delays due to regional regulations concerning water discharge, heat emissions, or construction standards.

Overcoming these barriers requires both strategic investment and the adoption of new tools and technologies to streamline system design and monitoring. One such transformative solution is Computer-Aided Design (CAD).

How CAD Technology Enhances Heat and Water Optimization

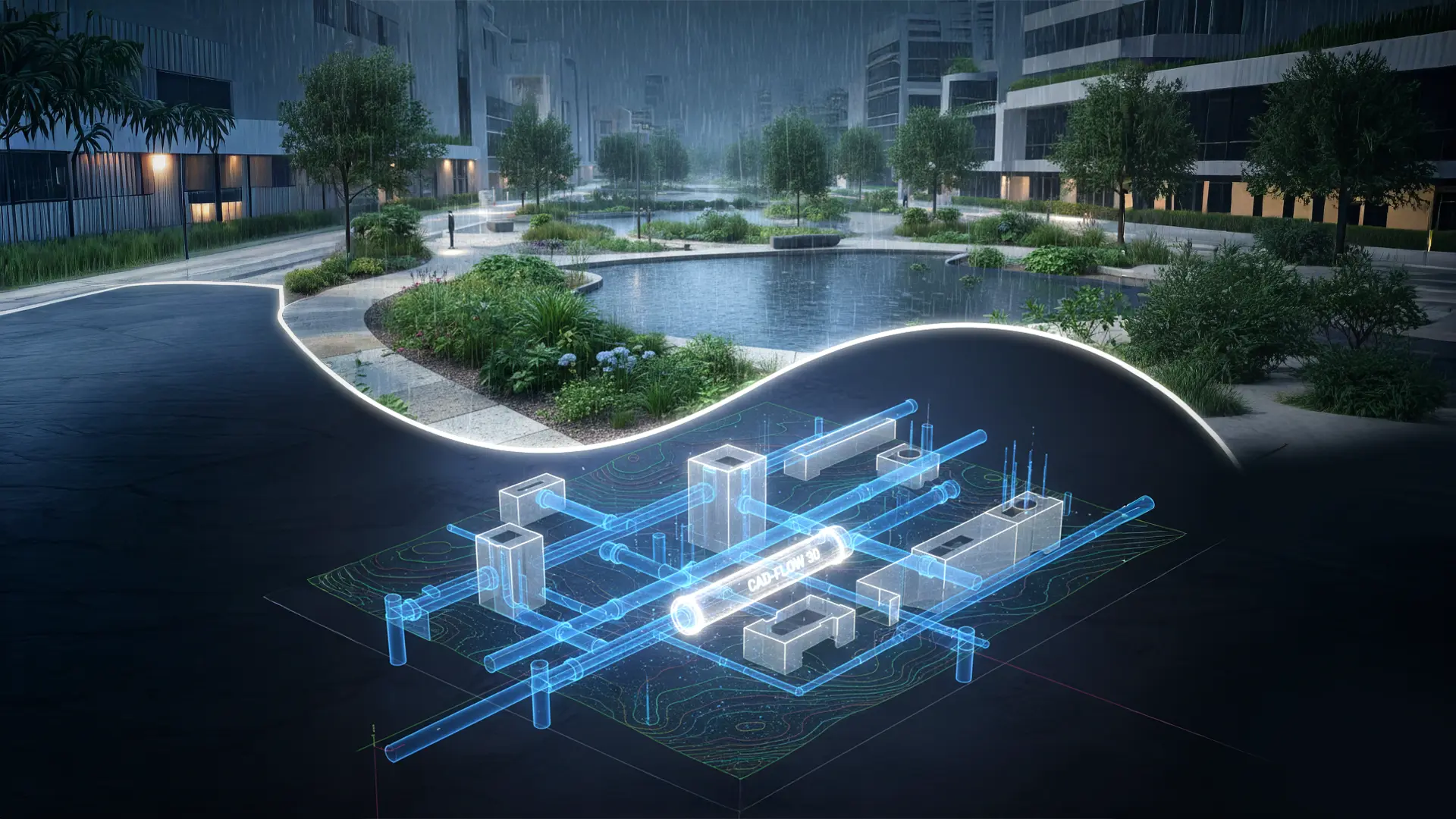

One of the most powerful tools in addressing these challenges is CAD. CAD software enables engineers to design, simulate, and optimize every aspect of a biogas plant before construction begins. When applied to heat and water systems, CAD brings multiple benefits:

Detailed System Visualization: CAD models help visualize thermal and hydraulic pathways, identifying opportunities for heat recovery and water reuse.

Simulation Capabilities: Integration with tools like Computational Fluid Dynamics (CFD) allows analysis of fluid behaviour, pressure drops, and temperature distribution in pipes and vessels.

Optimized Layouts: Engineers can experiment with the placement of heat exchangers, pipelines, storage tanks, and pumps to minimize losses and maximize reuse.

Conflict Detection: CAD allows clash detection to avoid costly errors during construction, especially in compact or retrofitted plants.

Beyond the design phase, CAD tools integrated with Building Information Modelling (BIM) can provide real-time data for plant operators. This includes temperature trends, flow rates, and equipment efficiency, all of which are critical for maintaining optimized operations. Predictive maintenance can also be planned more effectively when data-driven models are used to anticipate system failures.

In short, CAD transforms the approach to heat and water optimization from reactive management to proactive, precision-driven design. It equips operators and designers to make informed decisions that improve both performance and sustainability.

Automation and Smart Controls

Modern automation technologies further enhance the benefits of good design. Supervisory Control and Data Acquisition (SCADA) systems allow real-time monitoring and control of plant operations. Sensors installed throughout the plant provide continuous data on temperature, pressure, flow rates, and water quality.

Using this data, automated systems can adjust heat inputs, trigger water recycling loops, or send alerts when parameters fall outside of optimal ranges. This reduces the need for manual intervention and ensures a consistent, efficient operation.

Integration of IoT devices, cloud computing, and machine learning can also lead to smarter control algorithms that learn and adapt over time, enhancing overall plant performance.

Optimizing heat and water exchange is crucial for the economic and environmental success of biogas plants. From improving energy recovery to reducing water usage, these efforts contribute significantly to sustainability goals. The integration of CAD technologies and automation tools allows operators to design smarter, run more efficiently, and adapt quickly to new challenges. As the renewable energy sector grows, such intelligent resource management will become increasingly central to the future of biogas production.