From Scarcity to Abundance: CAD’s Transformative Role in Desalination Plant Design

With freshwater scarcity rising, desalination is no longer a luxury, it’s a necessity. But designing a plant that efficiently converts seawater into drinkable water isn’t just about pipes and filters; it’s about precision, optimization, and innovation. This is where CAD (Computer-Aided Design) becomes the silent architect, transforming complex ideas into reality. By integrating CAD tools and partnering with CAD Connect, engineers can streamline design processes, enhance plant efficiency, and reduce costs. How does this collaboration shape the future of desalination? Let’s explore the digital backbone of modern desalination plant engineering!

Water Scarcity and Desalination: A Comprehensive Overview

Water scarcity is defined as the lack of freshwater resources to meet the standard water demand within a specific area. It occurs when there are insufficient freshwater resources to meet the human and environmental demands of a certain area. The concept of water scarcity is relative, as the amount of water that can be physically accessed varies as supply and demand changes. This global issue is caused by a combination of natural and human-made factors that reduce water availability. These factors include poor water management, population growth, and climate change, which collectively contribute to decreased water resources.

Desalination offers a solution to water scarcity by providing an alternative source of freshwater. It is defined as the process of removing salts and other minerals from water, making it suitable for human consumption, irrigation, or industrial uses. The basic principle involves the separation of salt and other impurities from seawater or brackish water to produce clean drinking water. This technology allows communities to use a broader variety of water sources than conventional techniques, thereby improving the resilience of water-stressed regions

Main Desalination Technologies

There are two main categories of desalination technologies: thermal processes and membrane-based processes. Thermal desalination involves heating water so that it evaporates into steam, leaving behind impurities, which then condenses back into liquid form for human use. This category includes technologies such as Multi-Stage Flash (MSF), Multi-Effect Distillation (MED), and Vapor Compression (VC).

Membrane-based desalination, particularly reverse osmosis (RO), is currently the most widely used technology globally. Reverse osmosis uses semipermeable membranes that allow water to pass through but retain salt and other contaminants. This process is more energy-efficient than thermal methods but still requires substantial pressure to force water through the membranes. More than two-thirds of desalination facilities nationwide are brackish water reverse osmosis facilities.

Challenges in Desalination

Technical Challenges:

Desalination requires high energy consumption, especially for reverse osmosis (RO) and thermal methods, making it expensive and resource intensive. Membrane fouling and scaling reduce efficiency, leading to frequent maintenance. The infrastructure demands are significant, requiring large-scale investment and ongoing operational costs. Additionally, water recovery rates are low, with only 40-50% of input water being converted into freshwater.

Economic Challenges

The high capital and operational costs make desalination less viable compared to traditional water sources. Energy dependency further increases costs, especially as fuel prices fluctuate. Many desalination projects require government subsidies or private investments to remain financially sustainable, making long-term affordability a challenge.

Environmental Challenges

Brine disposal is a major concern, as the highly concentrated saltwater discharge harms marine ecosystems. Most desalination plants rely on fossil fuels, contributing to greenhouse gas emissions. Additionally, water intake structures can trap and kill marine organisms, disrupting local biodiversity.

Social & Policy Challenges

Public resistance arises due to environmental concerns, high costs, and potential health risks from desalinated water byproducts. Strict regulations and lengthy permitting processes delay project implementation. Moreover, desalinated water remains unaffordable for many, leading to unequal access in water-scarce regions.

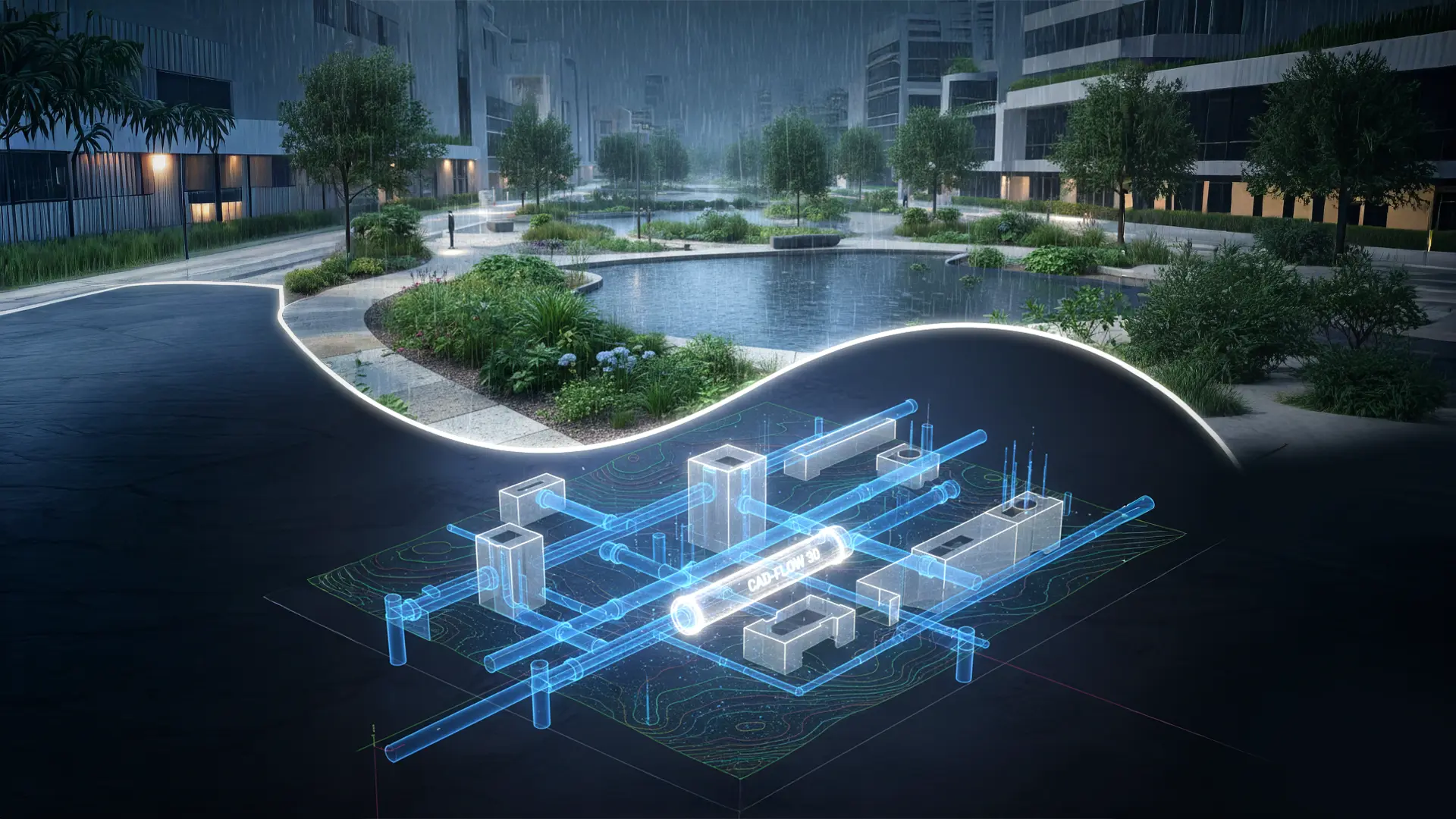

Importance of CAD in water treatment and desalination.

Computer-Aided Design (CAD) plays a crucial role in the development, optimization, and implementation of water treatment and desalination systems. It enhances the efficiency, precision, and scalability of infrastructure projects. Here’s why CAD is essential in this field.

Enhanced Design Accuracy and Visualization

CAD software allows engineers to develop precise 2D and 3D models of water treatment plants, pipelines, and desalination systems, ensuring accurate planning and execution. It provides detailed visualizations that help stakeholders assess layouts, equipment placement, and process flows before construction, reducing errors and improving efficiency. By identifying potential design flaws early, CAD minimizes costly modifications and enhances overall project reliability.

Process Optimization and Simulation

CAD, when integrated with simulation tools like Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA), helps optimize membrane performance, filter efficiency, and piping networks. Engineers can simulate water flow behavior, pressure losses, and energy consumption, ensuring efficient system design. Additionally, it aids in optimizing chemical dosing processes and sludge management, leading to improved water treatment effectiveness.

Sustainable and Cost-Effective Design

By optimizing reverse osmosis (RO) membrane arrangements and pump operations, CAD enables the design of energy-efficient desalination systems. It reduces material wastage through precise dimensioning and layout planning while supporting the integration of renewable energy sources like solar and wind. These capabilities ensure sustainable and cost-effective water treatment solutions.

Customization for Different Environments

CAD enables the design of modular and adaptable water treatment solutions suitable for diverse environments, including urban, rural, and industrial applications. It supports the development of portable and decentralized desalination units, making clean water accessible in remote or emergency locations.

Top CAD Software for Desalination Plant Design

Autodesk Plant Design Software: Autodesk offers a suite of tools for plant design, including AutoCAD, Revit, and Civil 3D. These tools provide powerful BIM and CAD capabilities for detailed design and documentation.

Bentley Plant Design Work Suite: This collection includes Open Plant Modeler, Open Plant PID, and Bentley Raceway and Cable Management, offering integrated solutions for 3D plant design and analysis.

Hexagon CADWorx®: Developed by Hexagon PPM, CADWorx is known for its ease of use and flexibility, widely utilized in process and power industries for plant and piping design solutions.

Smap3D Plant Design: Fully integrated with SOLIDWORKS, Smap3D covers the entire process from P&ID to Piping to Isometrics, making it suitable for environmental and water technology projects, including desalination plants

Conclusion

The future of water desalination isn’t just about removing salt, it’s about designing smarter, more efficient, and sustainable systems. CAD is at the heart of this transformation, enabling engineers to create optimized plant layouts, reduce energy consumption, and improve long-term reliability. With innovations like advanced membrane technology and energy recovery systems, desalination is becoming more cost-effective and eco-friendly than ever before.

Partner with CAD Connect to optimize every stage of desalination, from planning to execution. Don’t just keep up with innovation, lead it. Are you ready to shape the next wave of water technology?