The Role of CAD in Developing Advanced Water Treatment Systems.

With the exigency of high population growth and industrialization, pollution, and climate change, the need for clean water is more pressing than ever. It is not only necessary to improve the accessibility of clean water, but it is also critical to the advancement and operation of water treatment facilities, which calls for the utilization of novel technologies including Computer-Aided Design (CAD). CAD provides one of the most innovative and powerful methods to create advanced, hi-tech, and high-quality water treatment capabilities, and CAD can optimize the smooth integration of both technical and procedural elements, which ensures optimal design and operation of water treatment facilities. So, Looking for sustainable and progressive water treatment designs? You are at the right spot. This blog post introduces and investigates the capabilities of CAD and their preponderance regarding the design, operation, and sustainability of water treatment systems, and provides future perspective and research directions.

Understanding CAD and its advantages:

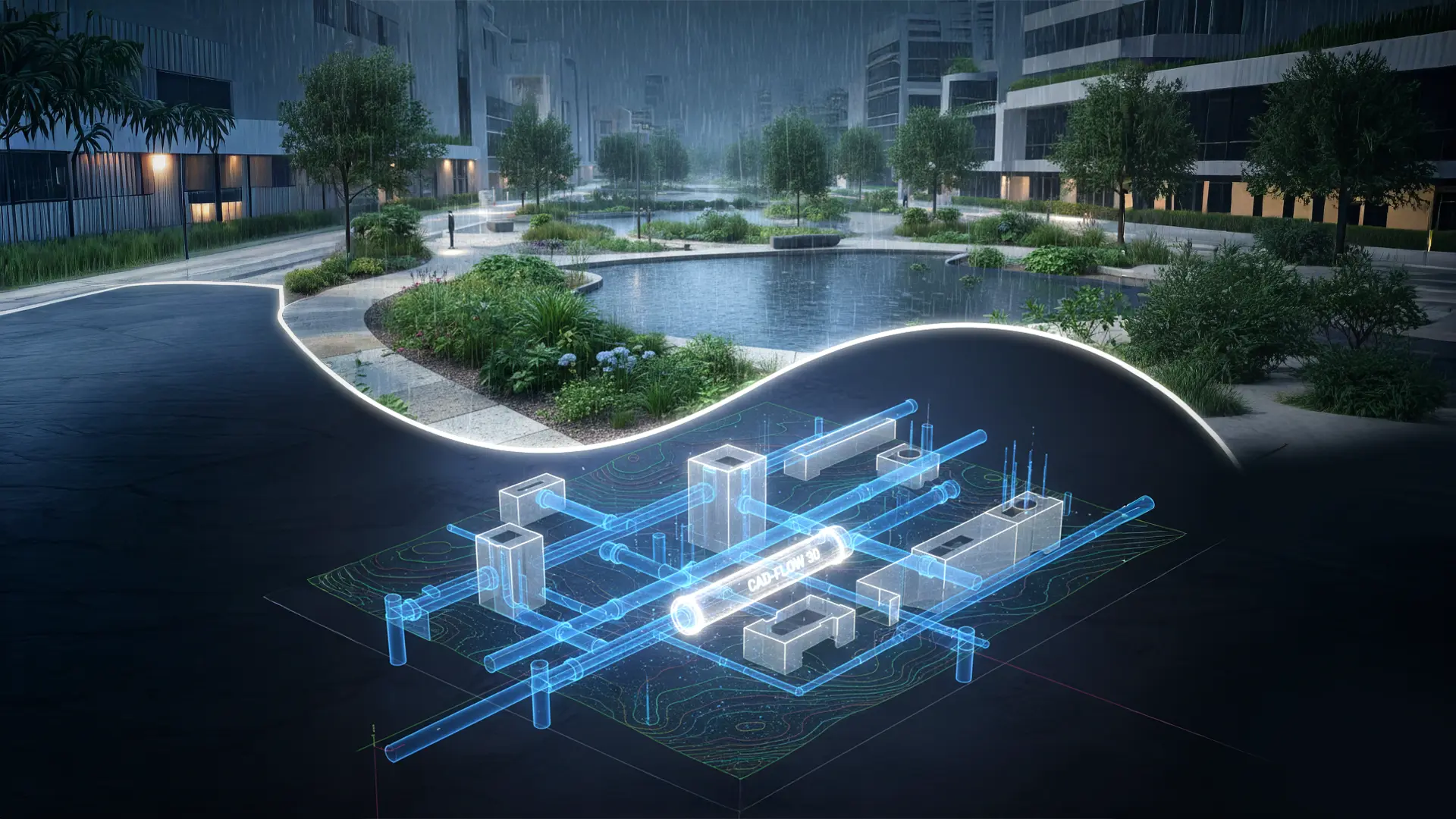

Computer-aided design (CAD) is an extensive technology applicable to several engineering fields that allow designers to draw, modify, model, simulate, and optimize precise digital representations of products, architecture, or systems. CAD software has simulation, analysis, and iterative design capabilities that can decrease, as well as eliminate, the requirement for physical prototypes, thereby speeding up and making the design process more accurate. CAD can help water treatment by designing infrastructure, equipment, and techniques that maintain water quality and sustainability. Now, let’s investigate the most important benefits one can acquire by applying CAD to water treatment.

Accuracy and Precision: Computer-aided design (CAD) allows the creation of highly accurate, precise, and detailed design models, thereby minimizing the likelihood of inherent errors associated with human drafting. This is of particular importance when designing water treatment systems, as the way each component fits within the larger system affects its ability to operate as intended. CAD enables all elements of the system to be designed in 3-D and in great detail, with the ability to validate these at multiple angles to assess whether flaws exist, enabling the design of the system to be vetted for all possible faults before any physical objects are built and any errors can be corrected, without a prototype needing to be built. In reducing the need to create and evaluate prototypes, the likelihood of making errors associated with human drafting is also reduced, which in turn reduces the material and labour wasted during development.

CAD enables detailed design of systems in terms of what filters and dosing systems are used, how the system is fed with flow paths, what support systems are required set with an accurate layout, and thus ensure the overall system operates correctly and meets the necessary water quality standards.

Simulation and Analysis:

Combining CAD models with simulation and analysis software enables engineers to study the performance of their designs in different scenarios. In water treatment, simulating water flow, pressure, temperature variations, and chemical reactions in the system will be useful in determining how systems will operate under real-world scenarios, and highlight potential issues early.

With CAD simulations, engineers can predict how different contaminants will interact with chemical treatments, how sludge will settle, and how treated water will flow in the system. Therefore, engineers can optimize treatment processes, improve efficiency, and lower operating costs.

Customization and Flexibility:

Water quality improvement projects have many industry-specific requirements, which can be dependent on many factors such as the source water, contaminant profile, project goals, and the intended target water quality standards for the project. Fortunately, CAD has the capability and versatility to accommodate these project-specific demands. Designers could begin with an existing design and modify the design to fit the site-specific conditions or design a new treatment unit that is optimal for a variation of source water.

In all cases, it is important to consider the water quality, treatment processes, receiving water quality, and operating conditions, so that the system designer can consider these aspects in the design to allow the designer of a system to mask these concerns in the best way they can.

Optimizing Component Layout:

The design of the system components has a considerable impact on the efficiency and effectiveness of water treatment systems. CAD is useful in creating energy–efficient and optimized system layouts with the best material savings. By simulating multiple layouts, engineers can determine the best placements for pumps, filters, piping, and other system components. CAD allows for the exploration of any number of design options and the ability to determine the best layout to maximize the system’s effectiveness, while also meeting the water quality requirement.

Reducing Physical Prototypes:

CAD enables the creation and testing of virtual models that allow engineers to ensure the final physical system behaves in desired ways without the need for physical prototypes. This reduces the time and cost of creating multiple physical prototypes, especially for the geometries and processes that are complicated, costly, and time-consuming.

Additionally, the potential interactions of the treatment agents and the constituents of the water being treated can be investigated to better understand what treatment agents would be effective in removing the environmental contaminants.

Streamlining Collaboration:

Water treatment projects typically consist of multidisciplinary teams of civil, mechanical, and chemical engineers, and environmental scientists. CAD is ideal for helping to establish collaboration among these diverse groups of workers.

The CAD files can be easily shared, remarked, and revised by the team members to ensure that everyone is working with the correct information. CAD allows all teams to work on their specialized design areas to combine their designs, working together to make sure that each part of the design matches up with the next.

Efficient Resource Utilization :

Sustainability is a paramount consideration in contemporary water treatment projects. CAD contributes to sustainability by enabling more efficient use of resources. By optimizing designs for energy efficiency and minimizing material waste, CAD helps reduce the environmental impact of water treatment systems.

Reducing Environmental Impact

Water treatment systems can have a significant environmental impact. Energy consumption, chemical usage, and wastewater discharge are all important environmental aspects of systems. CAD permits the creation of systems that reduce the environmental impact, by increasing efficiency and using innovative technologies.

Facilitating Innovation

Computer-aided design (CAD) plays a vital role in nurturing innovation in water treatment. By providing a forum for exploring new concepts and experimenting with innovative ideas, CAD allows engineers to push the envelope of what is conceivable.

This innovation is essential to the development of advanced water treatment technologies that can resolve emerging challenges and satisfy the need for clean water that is on the rise.

CAD has been a critical resource for developing hybrid treatment systems that combine different technologies such as membrane filtration, advanced oxidation, and biological treatment. These systems offer improved performance and flexibility over traditional treatment methods.

Future Scopes and Advancements in CAD for Water Treatment:

Integration with Emerging Technologies

The future of computer-aided design (CAD) in water treatment will be in the fusing with modern technology. This encompasses, of course, artificial intelligence (AI) and machine learning (ML), but also the Internet of Things (IoT). AI and ML aid CAD software by giving it predictive analytics, using historical data to optimise designs, and automating repetitive tasks. Implementing IoT can allow us to monitor and control water treatment systems in real time, which presents a chance to be more responsive and adaptive in system designs.

Moreover, AI algorithms can analyse large data sets of historical water treatment projects to suggest and uncover improvements by recognising trends. IoT sensors can obtain real-time feedback on system performance, which provides engineers with real-time information when making decisions during the design process.

Advanced Materials and Processes

The advance of chemicals, technology, and advances in CAD technology are continuously advancing wastewater treatment design. The advancement in CAD technology will allow for the design and implementation of wastewater treatment systems utilizing these advanced materials and processes, such as emerging technologies of forward osmosis, capacitive deionization, and advanced oxidation-reduction technologies to be advanced. Newly designed membrane materials have been made to have excellent permeability and selectivity.

These advances in CAD technology aren’t the only advancements in water and wastewater treatment design and test that CAD skills will be helpful to be effective. The advancement in CAD technology will allow for the design and planning of innovative processes utilizing new materials and technologies. These advances are significant due to the opportunities to produce new, innovative, and cost-effective water and wastewater treatment technologies. CAD technology is and will be key to moving this type of technology to the practical application for the professional.

Enhanced Collaboration and Cloud Computing

Cloud computing is influencing the direction CAD systems are taking, now there is a growing trend towards such systems exploiting increased collaboration using cloud-based platforms. Thanks to the fact that cloud-based CAD platforms enable project engineers and stakeholders to work together simultaneously regardless of where they might be. This is also of significant benefit for the large-scale water treatment projects’ international teams and the project logistics that are involved.

Furthermore, cloud computing could also enable engineers to run more powerful simulations and analyses due to the increased computational capacity. Engineers could run powerful models, which previously could have been complex and not necessarily runnable on standard desktops, as a result potentially meaning that optimized designs can be generated or at least improved upon while keeping project timelines in check.

Virtual and Augmented Reality

VR- Virtual Reality and AR- Augmented Reality are being increasingly identified as next-generation tools for CAD. Specific to VR, users can be situated into a fully digital setting that provides a deep, immersive experience where the designs come to life more creatively. With AR, the CAD information is overlaid on the physical world, providing real-time data and insights to assist in the construction and maintenance phases.

For the water treatment industry, VR and AR provide opportunities to train plant operators, visualize complicated systems, and present the ability to maintain and troubleshoot more effectively, all improving the usefulness of the CAD models, making them more attainable, and practical to broader audiences.

Sustainable and Resilient Design

Given concerns about climate change and population growth putting stress on water resources, the importance of sustainable and resilient design in water treatment will continue to rise. Computer-aided design (CAD) will provide critical support in the design of systems with the ability to adapt to changing conditions and operate sustainably into the near future.

Advancements in CAD will include more advanced tools to support lifecycle analysis, resource optimization, and resilience modelling that will support engineers to design water treatment systems that are not only effective now, but also capable of effectively addressing future challenges.

Conclusion:

The use of CAD is one of the most critical tools for engineers and researchers in the water treatment field because it enables increased design precision, maximizes system performance, and improves sustainability. The potential for CAD tools to help deliver more efficient, effective, and sustainable water treatment technologies to meet current and future global water challenges is significant. Water treatment remains a dynamic field that will require innovative and out-of-the-box solutions. Therefore, as we continue to incorporate new materials, data sources, and technologies, CAD software and platforms are viewed as essential tools that will advance along with the field ensuring advances in the efficient, effective, and sustained operation of treatment systems.

However, what is more important is your association with a trusted CAD engineering solutions partner, that strives for delivering the best solution to you. CAD Connect, with a legacy of serving sophisticated designs and architecture based on the latest of technologies, is a solution partner you can rely on for perfect and sustainable CAD designs for your water treatment facilities. Connect with us for initiating life-long relationship of trust, excellence and expertise.